Tungsten Nickel Iron Alloy Rod and Bar (90W7Ni3Fe, 97W2Ni1Fe)

Tungsten Nickel Iron Alloy Rod and Bar (W-Ni-Fe) are high-density materials composed of tungsten (W), nickel (Ni), and iron (Fe), offering exceptional strength, corrosion resistance, and thermal conductivity. These alloys are available in various compositions with tungsten content ranging from 90% to 97% for optimal performance in demanding applications. Our Tungsten Nickel Iron Alloy products comply with ASTM, ISO, and other industry standards, ensuring superior quality and reliability. These rods and bars are ideal for aerospace, defense, radiation shielding, and high-performance mechanical components. Princeton Powder is a trusted supplier offering customized sizes and shapes to meet specific application needs. We provide Tungsten Nickel Iron Alloy Rod and Bar for sale at competitive prices, delivering high-quality materials to industries worldwide.

Material | Tungsten Nickel Iron Alloy |

CAS Number | 7440-33-7 |

Content | 90-97W-Ni-Fe |

Purity | 99.5% – 99.95% |

| Density | 17.1-18.5 g/cm3 |

Melting Point | 3422 ℃ |

Dimensions | Customized |

Surface Treatment | Pickling or Polishing |

Description of Tungsten Nickel Iron Alloy Bar

Tungsten Nickel Iron Alloy Bar (W-Ni-Fe) offers high density, strength, and excellent thermal conductivity. It is ideal for applications requiring radiation shielding, counterweights, and vibration damping. The alloy is highly durable and corrosion-resistant, making it suitable for aerospace, defense, and nuclear industries. It also provides superior mechanical strength and thermal conductivity for use in electrical contacts and high-performance components. Custom sizes and shapes are available for various industrial applications.

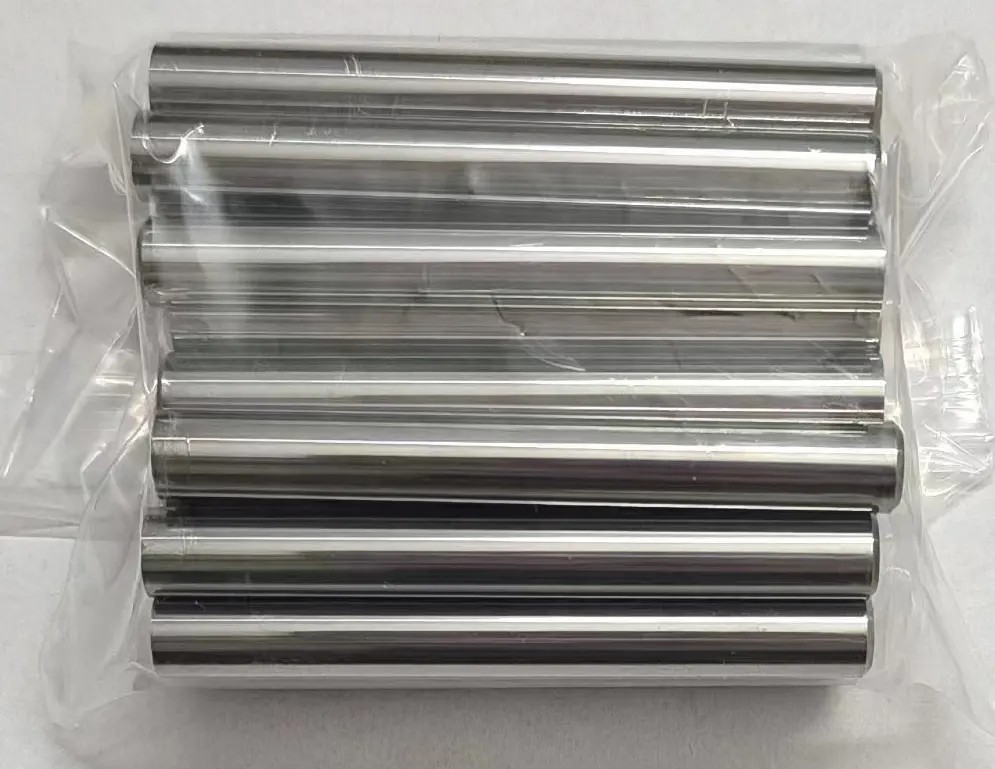

Tungsten Nickel Iron Alloy Bar 97W-2Ni-Fe Product

| Materials | 90W-7Ni-3Fe | 92W-5Ni-3Fe | 93W-4Ni-3Fe | 95W-3Ni-2Fe | 97W-2Ni-1Fe | customized |

| Plate | √ | √ | √ | √ | √ | √ |

| Sheet | √ | √ | √ | √ | √ | √ |

| Strip | √ | √ | √ | √ | √ | √ |

| Rod | √ | √ | √ | √ | √ | √ |

| Sputtering Target | √ | √ | √ | √ | √ | √ |

| Tube | √ | √ | √ | √ | √ | √ |

Tungsten Nickel Iron Alloy Sheet W-Ni-Fe Specification

| ASTM B777-15 | Non-magnetic Class 1 | Non-magnetic Class 2 | Non-magnetic Class 3 | Magnetic Class 1 | Magnetic Class 2 | Magnetic Class 3 | Magnetic Class 4 |

| AMS 7725E | Type 1 Class 1 | Type 1 Class 2 | Type 1 Class 3 | Type 2 Class 1 | Type 2 Class 2 | Type 2 Class 3 | Type 2 Class 4 |

| MIL-T-21014 Rev D | Class 1 | Class 2 | Class 3 | Class 1 | Class 2 | Class 3 | Class 4 |

| SAE-AMS-T-21014 | Class 1 | Class 2 | Class 3 | Class 1 | Class 2 | Class 3 | Class 4 |

| Tungsten (wt%) | 90 | 93 | 95 | 90 | 92.5 | 95 | 97 |

| Binder | Ni/Cu | Ni/Cu | Ni/Cu | Ni/Fe | Ni/Fe | Ni/Fe | Ni/Fe |

| g/cm3 | 17.10 | 17.60 | 17.90 | 17.10 | 17.50 | 18.10 | 18.50 |

| lb/in3 | 0.62 | 0.64 | 0.65 | 0.62 | 0.63 | 0.65 | 0.67 |

| Hardness, HRC | 24 | 24 | 24 | 27 | 24 | 24 | 25 |

| Mpa | 675 | 650 | 680 | 645 | 645 | 660 | 660 |

| ksi | 100 | 95 | 100 | 95 | 95 | 95 | 95 |

| Mpa | 805 | 830 | 805 | 875 | 900 | 910 | 915 |

| ksi | 116 | 120 | 116 | 126 | 130 | 131 | 132 |

Tungsten Nickel Iron Alloy W-Ni-Fe Properties

| 90W7Ni3Fe | 91W6Ni3Fe | 92W5Ni3Fe | 93W4Ni3Fe | 95W3Ni2Fe | 96W3Ni1Fe | 97W2Ni1Fe | |

| Elongation (%) | 18-29 | 17-27 | 16-26 | 16-24 | 10-22 | 8-20 | 6-13 |

| Hardness (HRC) | 24-28 | 25-29 | 25-29 | 26-30 | 27-32 | 28-34 | 28-36 |

| Density (g/cm3) | 17.1±0.15 | 17.25±0.15 | 17.50±0.15 | 17.60±0.15 | 18.10±0.15 | 18.30±0.15 | 18.50±0.15 |

| Tensile Strength (MPa) | 900-1000 | 900-1000 | 900-1100 | 900-1100 | 920-1100 | 920-1100 | 920-1100 |

Tungsten Nickel Iron Alloy W-Ni-Fe Application

Counterweights and Ballasts: Used in aerospace, automotive, and industrial applications for creating compact and efficient counterweights to improve balance and stability.

Radiation Shielding:Applied in nuclear and medical industries for X-ray and gamma ray shielding, providing protection against harmful radiation.

Sintered Parts and Components:Used in the manufacturing of surgical instruments, turbine blades, and drilling equipment due to its durability, wear resistance, and high density.

Aerospace and Defense: Utilized in missiles, armor-piercing projectiles, and military equipment due to its high density and mechanical strength, making it ideal for impact-resistant applications.