Platinum Rhodium Crucible (Pt/Rh crucible)

Platinum rhodium (Pt-Rh) crucibles are made from platinum alloyed with 5-10% rhodium, offering enhanced strength and oxidation resistance for extreme temperatures up to 1,700°C. Available in cylindrical, boat-shaped, and custom designs, they’re widely used for single crystal growth, precious metal refining, and corrosive flux reactions in labs and industry. These crucibles come in various purity grades (99.9%-99.95%) and surface finishes (polished/matte) to suit specific applications.

Available in a variety of standard (5-700 ml) and custom sizes, these crucibles ensure uniform thermal conductivity, excellent durability, and minimal contamination during evaporation processes. Pt-Rh crucibles are for sale in competitive price.

Material | Platinum-Rhodium, PtRh5, PtRh10 |

Purity | 99.95%-99.99% |

Dimension | 5-100 ml |

Apperance | metallic silver |

Surface | Polished, Alkali Cleaning,Chemical Cleaning |

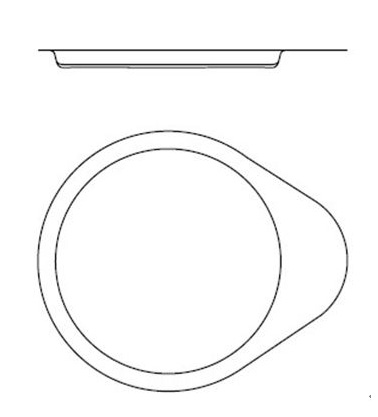

Form | Cylindrical platinum rhodium PtRh crucible Straight-walled platinum rhodium PtRh crucible Tapered platinum rhodium PtRh crucible Platinum rhodium PtRh boat crucible Platinum rhodium PtRh crucible with lid Platinum rhodium PtRh crucible with spout |

Certification | ISO9001 |

Description of Platinum Rhodium (PtRh) Crucible

The Platinum Rhodium (PtRh) Crucible is a high-temperature lab crucible crafted from premium Pt-Rh alloys (including PtRh5 and PtRh10), engineered to withstand extreme heat up to 1700°C+. Ideal for precious metal melting (gold, silver, platinum) and high-precision laboratory applications, this corrosion-resistant crucible delivers unmatched durability and oxidation resistance for long-term reliability. Widely used in metallurgy, material science, and semiconductor research, it excels in refining, alloying, and ultra-high-purity material testing. Princeton Powder offers tailored Pt-Rh crucible solutions to meet exact lab or industrial needs.

Platinum Rhodium (PtRh) Crucible Specifications

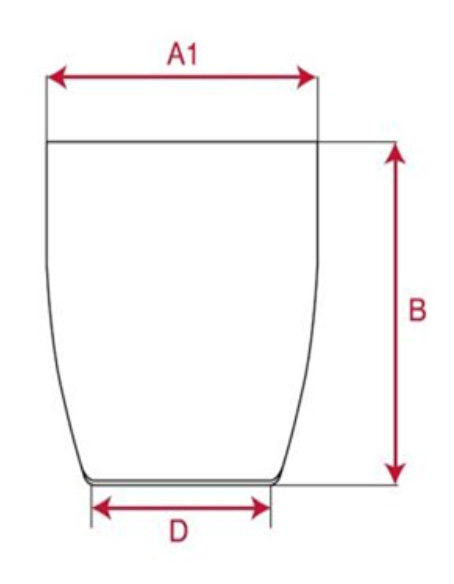

| Type | Top Diameter | Height | Bottom Diameter | Volume |

|---|---|---|---|---|

| PT-5 | A1=20 mm | B=22 mm | D=10 mm | 5 ml |

| PT-8 | A1=27 mm | B=22 mm | D=12 mm | 8 ml |

| PT-10 | A1=26 mm | B=27 mm | D=15 mm | 10 ml |

| PT-12 | A1=28 mm | B=31 mm | D=26 mm | 12 ml |

| PT-15 | A1=30 mm | B=33 mm | D=17 mm | 15 ml |

| PT-20 | A1=33 mm | B=35 mm | D=18 mm | 20 ml |

| PT-25 | A1=36 mm | B=36 mm | D=20 mm | 25ml |

| PT-30 | A1=36 mm | B=40 mm | D=22 mm | 30 ml |

| PT-35 | A1=41 mm | B=38 mm | D=24 mm | 35 ml |

| PT-40 | A1=42 mm | B=42 mm | D=25 mm | 40 ml |

| PT-45 | A1=43 mm | B=48 mm | D=26 mm | 45 ml |

| PT-50 | A1=45 mm | B=48 mm | D=27 mm | 50 ml |

| PT-60 | A1=45 mm | B=47 mm | D=29 mm | 60 ml |

| PT-70 | A1=49mm | B=53 mm | D=30 mm | 70 ml |

| PT-80 | A1=51 mm | B=53 mm | D=30 mm | 80 ml |

| PT-90 | A1=54 mm | B=57 mm | D=33 mm | 90 ml |

| PT-100 | A1=56 mm | B=57 mm | D=35 mm | 100 ml |

| PT-120 | A1=64 mm | B=66 mm | D=35 mm | 120 ml |

| PT-150 | A1=65 mm | B=69 mm | D=37 mm | 150 ml |

| PT-200 | A1=65 mm | B=80 mm | D=40 mm | 200 ml |

| PT-250 | A1=81 mm | B=73 mm | D=55 mm | 250 ml |

| PT-700 | A1=105 mm | B=105 mm | D=72 mm | 700 ml |

| The customized sizes can be porvided accroding to customers’ design. | ||||

Platinum Rhodium (PtRh) Crucible Crucible Application

Platinum Rhodium (Pt-Rh) Crucibles are essential high-temperature labware for precious metal melting (gold, silver, platinum) and advanced material research (single crystal growth, semiconductor synthesis). These ultra-durable crucibles withstand extreme temperatures up to 1700°C, making them ideal for XRF sample preparation, ICP-MS analysis, and catalyst testing. With superior corrosion and oxidation resistance, they’re widely used in metallurgy, aerospace, and nuclear research applications. Available in standard sizes (10mL-100mL) or as custom Pt-Rh alloy crucibles (PtRh5, PtRh10), they’re the top choice for high-purity industrial and laboratory processes.

Platinum Rhodium (PtRh) Crucible scholar article

Comparison of Platinum Laboratory Crucibles for Glass Melting (Case Study)

Abstract: Because of high melting temperature, oxidation and corrosion resistance, platinum crucibles are key tools for wide range of analytical procedures like dissolving in hot hydrofluoric acid, loss on ignition, ash testing and fusion of slag, mineral, cement and glass samples. Pure platinum is the basic material choice, offering relatively low price, on the other hand is quite soft and vulnerable to grain coarsening after prolonged high temperature exposure. Alloying with rhodium increase the material hardness and slows down grain growth, but can be significantly more expensive.