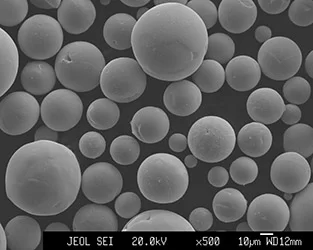

Spherical niobium-based alloy Nb521 Powder

Formula | Nb521 (Nb-5 W-2Mo-1Zr) |

Synonyms | spherical Nb521 particle, spherical Nb521 powder, Nb521 Powder, Nb521 thermal spray powder, Nb521 gas atomized powder |

Appearance | Black Powder |

Particle Size | 15-53 um, 45-105 um, can be customized upon request |

Melting Point | 2630°C |

Density | 8.9 g/cm 3 |

Tensile Strength, Ultimate | 623.6 MPa |

Tensile Strength, Yield | 340 MPa |

Description of Niobium 521 Powder

Niobium 521 powder, also known as Nb-5Zr-1Hf, is a niobium alloy with 5% zirconium and 1% hafnium. It features a high melting point of approximately 2,470°C and offers enhanced strength and oxidation resistance. This powder is used in aerospace components, nuclear reactors, and additive manufacturing for high-temperature applications. Its properties make it ideal for creating complex, high-performance parts.

Princeton Powder is a leading supplier of spherical Niobium 521 powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. Niobium 521 spherical powder is for sale in bulk.

Chemical Composition

Poduct | Chemical Composition (%) | ||||||||||||

Nb521 | Nb | Mo | W | Zr | Al | Fe | Si | Other | |||||

balance | 1.9 | 4.76 | 0.99 | <0.01 | <0.01 | 0.01 | <0.05 | ||||||

Gas Impurities (%) | |||||||||||||

C | H | O | N | ||||||||||

0.05-0.12 | <0.005 | <0.02 | <0.01 | ||||||||||

Physical Properties | |||||||||||||

Apparent Density (g/cm3) | Tap Density (g/cm3) | Hall Flow Rate (s/50g) | |||||||||||

>5.5 | >6.5 | <10.0 | |||||||||||

Particle Size | 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, or customized. | ||||||||||||

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

- Aerospace: Used in aerospace components requiring high temperature and stress resistance, such as rocket nozzles and heat shields.

- Nuclear Industry: Employed in nuclear reactors for its high temperature stability and resistance to radiation damage.

- Additive Manufacturing: Utilized in 3D printing to produce high-performance parts with complex geometries.