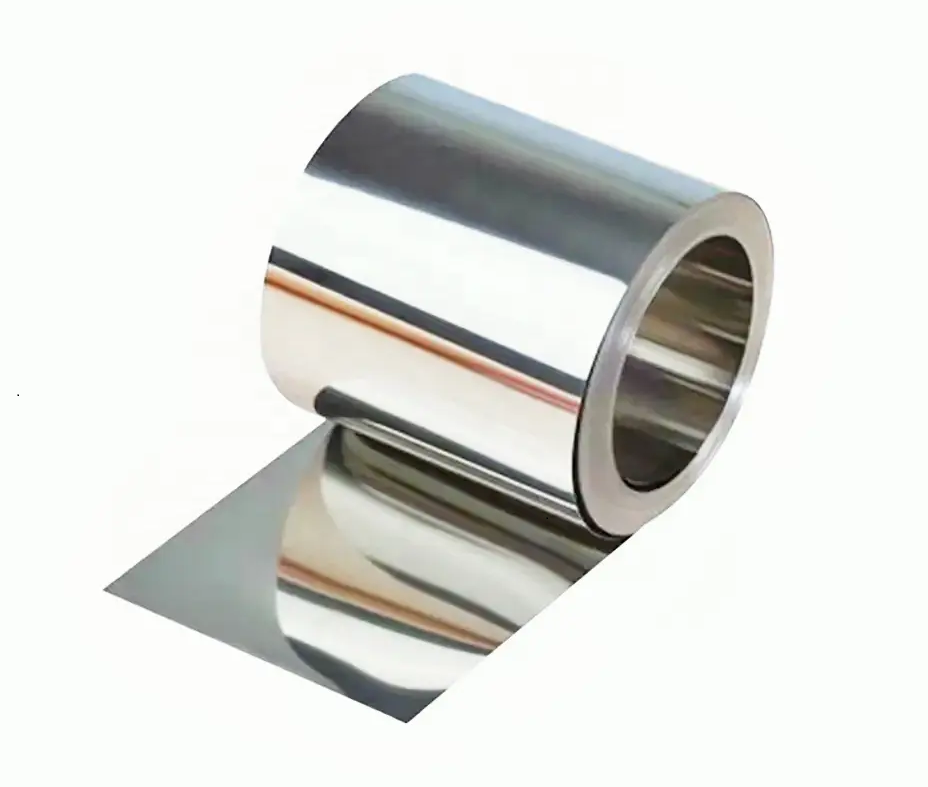

Niobium Foil, Strip, and Ribbon (Niobium metal and alloy)

Princeton Powder is a top supplier of high-purity Niobium Foil and Strip, offering both pure Niobium and alloyed varieties like niobium-titanium (Nb-Ti) and niobium-zirconium (Nb-Zr) foils, all manufactured to meet ASTM B393 standards. The production of niobium foils and strips involves advanced techniques like rolling, annealing, and cold rolling, ensuring precise thickness and flexibility. Additionally, surface treatments such as chemical etching and polishing are applied to achieve a smooth, defect-free finish. These products are ideal for applications in superconducting technology, electronics, and the medical field. Niobium foil and strip are available at competitive pricing.

Material | Niobium Foil, Strip, Ribbon |

CAS Number | 7440-03-1 |

Standard | ASTM B392 |

Color/Appearance | Gray, Metallic |

| Density | 8.57 g/cm3 |

Melting Point | 2468 ℃ |

Diameter | Customized |

Surface Treatment | Pickling or Polishing |

Description of Niobium Foil, Strip, and Ribbon (Rolling and Annealing, Cold Rolling)

Niobium foil and strip are thin, flexible forms of niobium, prized for their strength, flexibility, corrosion resistance, and superconductivity. Niobium, with atomic symbol Nb and atomic number 41, is known for its stability under extreme conditions and its unique ability to become superconducting at low temperatures.

High-purity niobium foil (up to 99.9%) is ideal for superconducting and corrosion-resistant applications, while alloyed types like Nb-Ti and Nb-Zr offer enhanced ductility. Production methods such as rolling, annealing, and cold rolling achieve precise thickness and flexibility. Chemical etching and polishing provide a smooth, defect-free surface, essential for electronic and medical applications. These foils remain stable under extreme conditions and demonstrate superconductivity at cryogenic temperatures.

Chemical Compositions of Niobium Foil, Strip, and Ribbon

Material

| Main elements(%)

| Impurities (Maximum %)

| ||||||||||

Nb

| Fe

| Si

| Ni

| W

| Mo

| Ti

| Ta

| O

| C

| H

| N

| |

RO4200

| Remainder

| 0.004

| 0.004

| 0.002

| 0.005

| 0.005

| 0.002

| 0.07

| 0.015

| 0.0040

| 0.0015

| 0.003

|

RO4210

| Remainder

| 0.01

| 0.01

| 0.005

| 0.02

| 0.01

| 0.004

| 0.10

| 0.02

| 0.01

| 0.0015

| 0.01 |

Physical Properties of Niobium Foil, Strip, and Ribbon

Grade | Tensile strength psi(MPa), ≥ | Yield strength δ0.2, psi (MPa),≥ | Elongation in 1″/2″ gage length, %, ≥ | |

>=0.010 | <0.010 | |||

RO4200, RO4210 | 18000 (125) | 12000 (85) | 25 | 20 |

Application

- Superconducting Devices – Niobium foils are used in superconducting magnets, such as those in MRI machines and particle accelerators.

- Electronics and Capacitors – Niobium’s stability and low reactivity make it ideal for capacitor anodes and other electronics requiring low contamination.

- Medical Equipment – Biocompatible niobium foils are used for implants and surgical instruments, reducing the risk of allergic reactions.

- Aerospace and Defense – Applied in sensitive components that require corrosion and heat resistance, like heat shields and protective layers.

How to select Niobium Foil, Strip, and Ribbon

Niobium foil and strip are chosen for advanced applications across medical, electronic, and scientific fields. The key parameters are below for choosing a best Nb ribbon, foil, and strip

Alloy Content

- For certain applications, alloyed foils such as Nb-Ti or Nb-Zr might be chosen to achieve higher ductility, durability, or improved superconducting properties

Thickness and Width

- Thin foils (down to micrometers) are preferred for precise electronic applications, while thicker strips are suitable for structural uses in harsh environments

Purity

- High-purity niobium (99.9% or higher) is essential in applications like superconductors and medical devices where material purity directly affects performance

Surface Finish and Smoothness

- A defect-free, smooth surface is crucial for medical, electronic, and superconducting applications to ensure functionality and compatibility