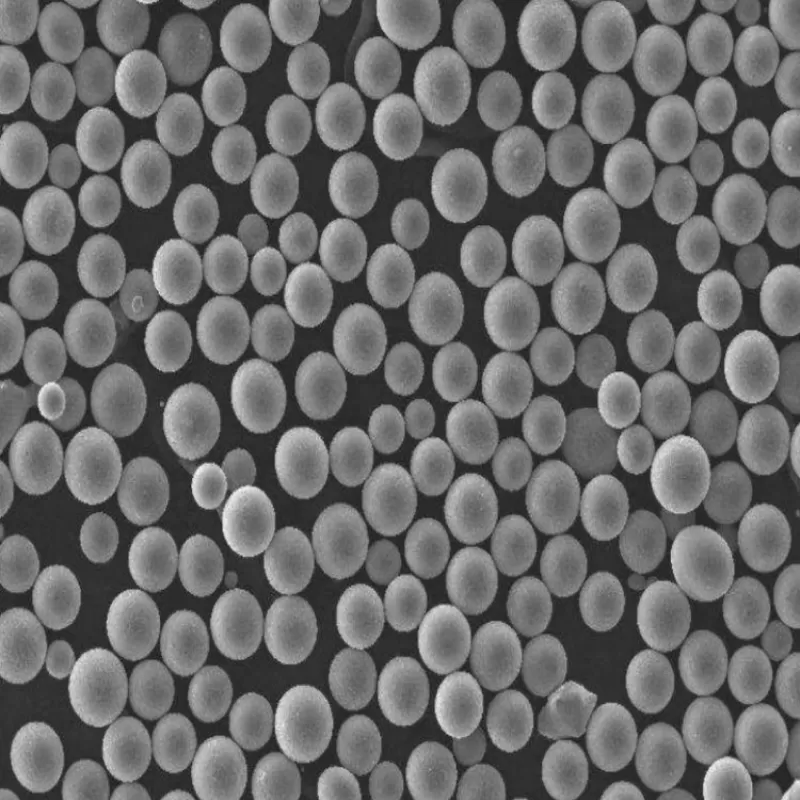

Commercially pure titanium Ti Spherical Powder

Formula | Titanium Ti |

Synonyms | CP titanium spherical particles, Commercially pure grade titanium powders, Ti spherical Powder, TA1 Titanium thermal spray powder, unalloyed titanium granules, Titanium metal powder |

Appearance | Black Powder |

Particle Size | 0-45 um, 45-105 um, can be customized upon request |

Melting Point | 1,688 °C |

Density | 4.5 g/cm 3 |

Tap Density | 2.8 g/cm³ |

Apparent density | 2.1 g/m3 |

Description of commercially pure titanium Spherical Powder

CP Titanium, also known as Commercially Pure Titanium, is a high-purity form of titanium metal with minimal alloying elements. Its composition includes 99-99.5% titanium, with trace amounts of iron, oxygen, carbon, and nitrogen. CP Titanium has excellent corrosion resistance, high strength-to-weight ratio, superior biocompatibility, and excellent ductility. These properties make it ideal for applications in aerospace, medical implants, and chemical processing. CP Titanium is available in four grades (1, 2, 3, and 4), each offering varying levels of strength and ductility to suit different industrial requirements.

Titanium powder is vital in advanced manufacturing, especially in additive manufacturing and 3D printing. Derived from Titanium Sponge Powder, it is processed into fine, consistent particles ideal for these applications. In additive manufacturing, titanium powder is used in techniques like Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Direct Metal Laser Sintering (DMLS) to build complex, high-precision components layer by layer.

Princeton Powder is a leading supplier of Titanium metal spherical powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. With our expertise, we are confident in supporting your projects effectively and provide you with reliable solutions.

Chemical Composition

Chemical Composition (wt%) | ||||||||||

Item | Fe | C | H | Si | Al | V | Mo | Sn | Zr | Ti |

TA1 | ≤0.1 | 0.08 | ≤0.015 | – | – | – | – | – | – | Bal. |

Oxygen≤1300 ppm; Nitrogen≤300 ppm

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

- Aerospace: Aircraft and spacecraft parts like turbine blades and engine components via additive manufacturing.

- Medical and Dental: Bio-compatible implants such as joint replacements and dental implants through 3D printing.

- Automotive: High-performance, lightweight parts for improved fuel efficiency and performance.

- Industrial: Corrosion-resistant equipment for chemical processing.

- Energy: Components for power generation, gas turbines, and nuclear reactors.

- Consumer Goods: High-end sports equipment, electronics, and jewelry.

- 3D Printing: Spherical powder for intricate, precise components with minimal waste.

Spherical Commercially pure titanium Powder Reference

Titanium powders used in powder bed fusion: Their relevance to respiratory health

- This study aimed to characterise three titanium powders used in powder bed fusion in terms of particle size, shape, and elemental composition for comparison with safety data sheet (SDS) information, and their relevance to additive manufacturing (AM) operators’ respiratory health.

GHS Classification (29 CFR 1910.1200): Flammable solids, category 1. Hazard Statements: H228 Flammable solid.

- Composition: Titanium powder is pure titanium, while titanium alloy powder includes additional elements to enhance properties.

- Properties: Titanium alloys typically offer improved strength, thermal stability, and other specific enhancements compared to pure titanium.

- Applications: Titanium alloy powders are used for more demanding applications requiring higher performance than what pure titanium can provide.

Metallic powders can be produced through one of several different processes, including grinding, crushing, electrolytic deposition, chemical reactions, and atomization. The size and shape of the particles is an important factor when designing a part for manufacturing by PM methods.