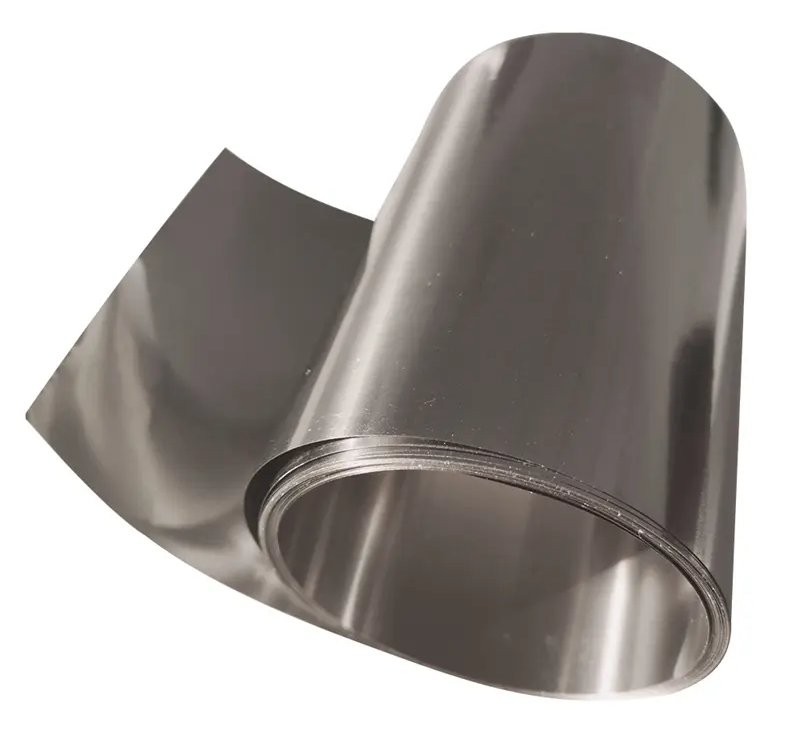

Titanium Foil, Titanium Strip (Grade 1, Grade 2, and Grade 5)

Princeton Powder is a premier supplier of titanium foil and strip in the United States, providing materials that comply with ASTM B265, AMS 4911, AMS 4901, and ASTM B348 standards. We offer titanium foils and strips in Grade 1, Grade 2, Grade 4, Grade 5 (Ti-6Al-4V), and Grade 23 (Ti-6Al-4V ELI). Our products undergo hot or cold rolling, followed by annealing, and are finished with surface treatments like pickling or polishing to meet customer specifications. We are committed to offering competitive pricing on our titanium foil and strip.

Material | Titanium Foil, Titanium Strip |

CAS Number | 7440-32-6 |

Standard | ASTM B265, AMS 4911, AMS 4901, ASTM B348 |

Grade | CP Titanium, Grade 5, Grade 7, Grade 9, Grade 23 |

| Density | 4.5 g/cm3 |

Melting Point | 1668 ℃ |

Thickness | Titanium Foil <0.01 inch Titanium Strip: 0.01 – 0.25 inch |

Manufacturing Process | Hot Rolling or Cold Rolling Annealing |

Surface Treatment | Pickling or Polishing |

Description of Titanium Foil, Titanium Strip

Titanium, identified by the symbol Ti and atomic number 22, is a shiny silver-gray metal celebrated for its remarkable blend of high strength, lightweight, excellent corrosion resistance, and biocompatibility. These qualities render it essential across various industries, including aerospace and medical sectors. Titanium is available in several grades, each designed with unique properties tailored for specific applications. These grades are classified according to their chemical composition and mechanical characteristics. Key grades include:

Grade 1: The softest and most ductile, known for its excellent corrosion resistance; commonly used in chemical processing, marine environments, and medical devices.

Grade 2: The most frequently used grade, offering a balanced combination of strength, ductility, and corrosion resistance; widely applied in aircraft construction and chemical processing.

Grade 3: Stronger than Grade 2, with slightly reduced ductility; suitable for industrial and marine applications requiring greater strength.

Grade 4: The strongest among commercially pure titanium grades, ideal for high-strength applications like aerospace components and medical implants.

Grade 5 (Ti-6Al-4V): The most prevalent titanium alloy, consisting of 6% aluminum and 4% vanadium; known for high strength, good corrosion resistance, and weldability, commonly used in aerospace and medical fields.

Grade 23 (Ti-6Al-4V ELI): Similar to Grade 5 but with lower impurity levels (Extra Low Interstitial), making it particularly suited for medical implants.

Grade 7: Comparable to Grade 2 but enhanced with palladium for improved corrosion resistance, especially in chemical processing applications.

Standard of Titanium Sheet, Titanium Plate

Titanium foil is produced according to various industry standards that ensure quality and performance. Key standards include:

ASTM Standards

- ASTM B265: Covers the specifications for titanium and titanium alloy sheet and plate, applicable to titanium foils as well.

- ASTM B348: Specifies requirements for titanium and titanium alloy bars, rods, and wire, which can relate to thickness and processing for foils.

AMS Standards

- AMS 4901: Covers the specifications for titanium foil, detailing the chemical composition and mechanical properties required for aerospace applications.

- AMS 4911: While focused on titanium alloy bars, it provides relevant insights into alloy compositions that can also apply to foil production.

ISO Standards

- ISO 5832-2: Pertains to commercially pure titanium used in medical implants, relevant for medical-grade titanium foils.

Titanium Grade 1 Sheet and Plate (Composition)

| Element | Composition (%) |

|---|---|

| Titanium (Ti) | Balance (99.5% min) |

| Oxygen (O) | ≤ 0.18% |

| Nitrogen (N) | ≤ 0.03% |

| Carbon (C) | ≤ 0.08% |

| Hydrogen (H) | ≤ 0.015% |

| Iron (Fe) | ≤ 0.20% |

Titanium Grade 2 Sheet and Plate (Composition)

| Element | Composition (%) |

|---|---|

| Titanium (Ti) | Balance (99.2% min) |

| Oxygen (O) | ≤ 0.25% |

| Nitrogen (N) | ≤ 0.03% |

| Carbon (C) | ≤ 0.08% |

| Hydrogen (H) | ≤ 0.015% |

| Iron (Fe) | ≤ 0.30% |

Titanium Grade 5 (Ti-6Al-4V) Sheet and Plate (Composition)

| Element | Composition (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5% – 6.75% |

| Vanadium (V) | 3.5% – 4.5% |

| Oxygen (O) | ≤ 0.20% |

| Nitrogen (N) | ≤ 0.05% |

| Carbon (C) | ≤ 0.08% |

| Hydrogen (H) | ≤ 0.015% |

| Iron (Fe) | ≤ 0.40% |

Titanium Grade 23 (Ti-6Al-4V ELI) Sheet and Plate (Composition)

| Element | Composition (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5% – 6.5% |

| Vanadium (V) | 3.5% – 4.5% |

| Oxygen (O) | ≤ 0.13% |

| Nitrogen (N) | ≤ 0.03% |

| Carbon (C) | ≤ 0.08% |

| Hydrogen (H) | ≤ 0.0125% |

| Iron (Fe) | ≤ 0.25% |

Titanium Sheet manufacturing and treatment processes

The manufacturing process for titanium foil involves several key steps to ensure high quality and precision. Here’s an overview:

Raw Material Preparation

- Titanium Sponge: The process begins with titanium sponge produced from titanium ore via methods like the Kroll process.

- Melting: The sponge is melted in a vacuum arc remelting (VAR) furnace to create titanium ingots.

Hot Rolling

- Initial Shaping: The ingots are heated and hot rolled into sheets. This step reduces thickness and enhances the material’s ductility.

Cold Rolling

- Further Reduction: The hot-rolled sheets are subjected to cold rolling to achieve the desired thickness for the foil. This process increases strength and improves surface finish.

Annealing

- Heat Treatment: The rolled foil is annealed to relieve internal stresses and enhance ductility. This involves heating the material to specific temperatures and then cooling it slowly.

Cutting and Finishing

- Trimming: The foil is cut to the required dimensions and may undergo further surface treatments such as pickling or polishing to achieve the desired finish.

Application

Titanium foil is widely used in aerospace for lightweight structural components and thermal protection due to its high strength-to-weight ratio. In the medical field, it serves in implants and surgical instruments, leveraging its biocompatibility and corrosion resistance. Additionally, it finds applications in electronics, chemical processing, and decorative items, showcasing its versatility across various industries.