Titanium 6Al-2Sn-4Zr-6Mo (Ti6246 or 6-2-4-6) Powder

Formula | Titanium 6Al-2Sn-4Zr-2Mo, Ti 6242, Titanium TA19 |

Synonyms | spherical Titanium 6242 particle, spherical Ti 6242 powder, Ti-6Al-2Sn-4Zr-2Mo Powder, Titanium 6242 thermal spray powder, Titanium 6242 gas atomized powder, Titanium TA19 powder |

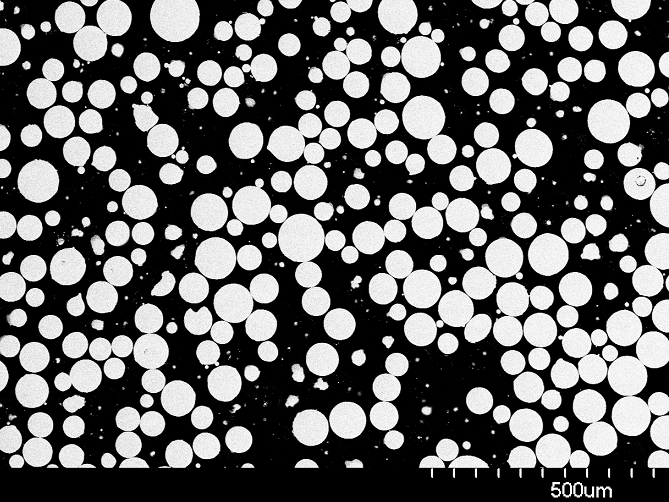

Appearance | Black Powder, Spherical shape |

Particle Size | 15-53 um, 45-105 um, can be customized upon request |

Melting Point | 1604-1670 °C |

Density | 4.43 g/cm 3 |

Apparent Density | 2.6-3.6 g/cm³ |

Tap Density | 4.6-5.6 g/cm³ |

Description of Spherical Titanium Alloy 6242 Powder

Spherical Titanium Alloy 6242 powder, also called Titanium Alloy 6-2-4-2 or Ti-6Al-2Sn-4Zr-2Mo powder, is a high-performance metal powder composed of titanium, aluminum (6%), tin (2%), zirconium (4%), and molybdenum (2%), with a small amount of silicon. Known for its exceptional strength, creep resistance, and stability at elevated temperatures, this alloy is particularly suited for aerospace and high-stress industrial applications. The powder’s spherical shape enhances flowability and packing density, making it ideal for additive manufacturing processes such as 3D printing, as well as for powder metallurgy and advanced coatings. Additionally, its excellent corrosion resistance and biocompatibility make it valuable for both structural components and medical implants.

Princeton Powder is a leading supplier of Titanium Alloy Ti 6242 powder. We specialize in a comprehensive range of spherical Titanium alloy powder products and possess extensive expertise in additive manufacturing (3D printing) industry. Titanium Alloy Ti 6242 powder is for sale at a competitive price in USA.

Chemical Composition

Chemical Composition Limits | |||||||||||

Weight % | Ti | Al | Sn | Zr | Mo | Fe | C | N | H | O | Others (total) |

TA19(Ti6242) | Balance | 5.5-6.5 | 1.8-2.2 | 3.6-4.4 | 1.8-2.2 | 0.25 | 0.05 | 0.04 | 0.015 | 0.15 | 0.3 |

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

Aerospace: TA19 is used in aircraft engine components, airframe parts, and structural components that require high strength and resistance to high temperatures.

Chemical Industry: Its corrosion resistance makes it ideal for equipment and piping in chemical processing plants.

Medical Implants: The alloy’s biocompatibility allows it to be used in orthopedic implants and other medical devices.

Spherical Titanium Based Ti TA19 Powder Reference

- Titanium alloys of near-α Ti–6Al–2Sn–4Zr–2Mo (Ti-6242) and intermetallic γ-TiAl (Ti–48Al–2Cr–2Nb) are commonly served as turbine blade materials operating at elevated temperatures. This study investigated the feasibility of using laser powder bed fusion (L-PBF) to fabricate two Ti–6Al–4V-based bimetals, i.e., Ti–6Al–4V/γ-TiAl and Ti–6Al–4V/Ti-6242, which may have great potential for the future manufacturing of aerospace components. Results indicated that the bimetal of Ti–6Al–4V/γ-TiAl was unsuccessfully built despite a gradient interface (∼250 μm) achieved via L-PBF.

Ti-6Al-2Sn-4Zr-2Mo (Ti-6242) and Ti-6Al-4V (Ti-64) are the two most commonly used alloys in aeroengines where the temperature reaches up to 300-450°C. Ti-6242 is preferred for higher temperature applications i.e. up to 450°C, owing to their excellent fatigue and creep resistance at elevated temperature.

Additive Manufacturing (3D Printing): Titanium 6242 powder is used in selective laser melting (SLM) or electron beam melting (EBM) processes to create complex, high-strength components layer by layer. The powder’s spherical shape ensures good flowability and packing density, crucial for producing precise and durable parts.

Powder Metallurgy: The powder is compacted and sintered to form solid components, which are then subjected to heat treatment to enhance mechanical properties. This process is used to produce parts with high structural integrity and excellent high-temperature performance.

Thermal Spray Coatings: Titanium 6242 powder is used in thermal spray processes, such as plasma spraying, to coat surfaces. This application enhances wear resistance, corrosion resistance, and high-temperature stability of the underlying materials, often used in aerospace and industrial machinery.

Titanium 6242 alloy powder (Ti-6Al-2Sn-4Zr-2Mo) offers high strength and creep resistance for high-temperature aerospace applications like gas turbines. Titanium 6246 alloy powder (Ti-6Al-2Sn-4Zr-6Mo) has higher molybdenum content, providing enhanced strength, fatigue resistance, and toughness, making it ideal for critical components like landing gear and deep-sea drilling equipment.