Tantalum-Tungsten Alloy Powder (Ta-10W, Ta-2.5W, Ta-7.5W Powder)

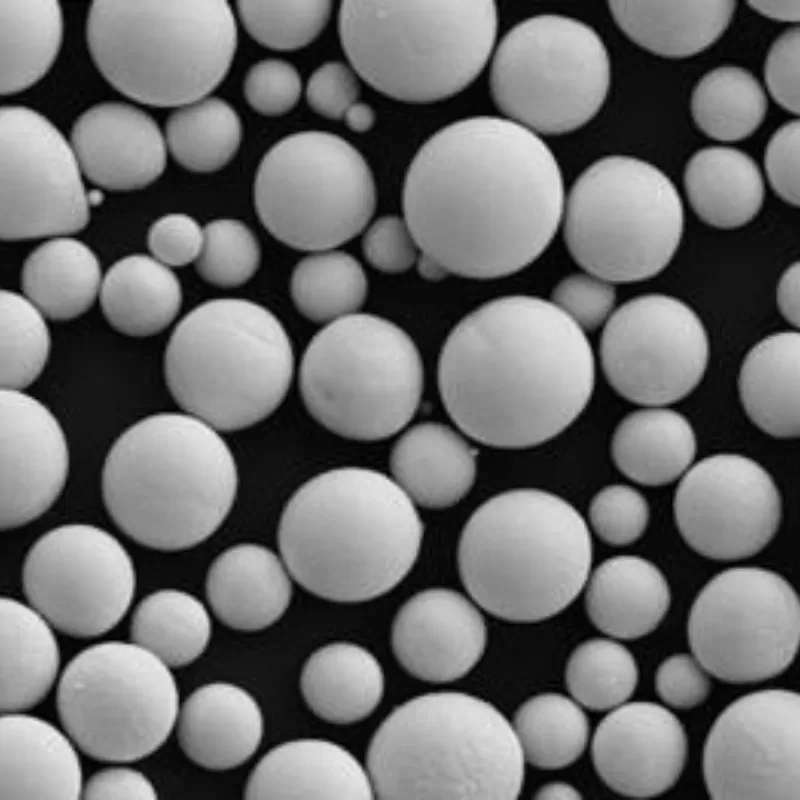

Tantalum tungsten alloy spherical powder is primarily composed of tantalum (Ta) and tungsten (W). This high-performance alloy typically features a tantalum content ranging from 90% to 98%, with the remainder being tungsten. The precise composition can vary depending on specific application requirements. The standard compositions include Ta-2.5W Tantalum tungsten powder, Ta-5.5W Tantalum tungsten powder, Ta-7.5W Tantalum tungsten powder, and Ta-10W Tantalum tungsten powder.

Princeton Powder is a leading supplier of Tantalum tungsten refractory powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. Ta10W spherical particle with 15-45 and 53-106 um is for sale at a competitive price.

Tantalum Tungsten Alloy Ta-W Spherical Powder

Formula | Ta10W, Ta2.5W, customized |

Synonyms | Ta10W spherical particles, Ta10W spherical powders, Ta2.5W Tantalum Powder, Tantalum Tungsten Alloy thermal spray powder, Tantalum Tungsten Alloy gas atomized powder |

Appearance | Black Powder |

Particle Size | 15-53 um, 45-105 um, can be customized upon request |

Melting Point | 3005-3030 °C |

Density | 16.7-16.9 g/cm 3 |

Purity | 99.95% min |

Tensile Strength | 550 MPa (Ta-7.5% W) |

Description of Tantalum Tungsten Alloy Spherical Powder

Tantalum tungsten alloy, often referred to as Ta-W alloy, is a high-performance material composed primarily of tantalum and tungsten. This alloy is known for its exceptional properties, including high melting points, excellent corrosion resistance, and remarkable strength and hardness.

Chemical Composition

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

- 3D Printing (Additive Manufacturing): The spherical powder form of tantalum tungsten alloy is ideal for 3D printing, allowing the production of intricate, high-strength components for aerospace, medical, and industrial applications.

- Aerospace Components: Its high strength and resistance to extreme temperatures make it suitable for critical aerospace components.

- Medical Implants: Due to its biocompatibility and corrosion resistance, it is used in medical implants and devices.

- Chemical Processing Equipment: Its resistance to corrosion makes it perfect for use in chemical processing equipment exposed to harsh environments.

- Electronics and Semiconductors: The alloy’s good electrical conductivity and stability are beneficial in electronic and semiconductor applications.

Spherical Tantalum Tungsten Alloy Powder Reference

Development of high densified tantalum-tungsten alloy by powder metallurgy route

- Ta and premixed Ta-3 wt%W powders were consolidated through spark plasma sintering (SPS) and hot pressing (HP) techniques at 2200 and 2000 °C, respectively. After density measurements, the samples were heat treated at 1100 °C for 4 h in vacuum atmosphere. The high densified PM tantalum and tantalum alloy were subjected to x-ray diffraction (XRD) examination, hardness, and Split Hopkinson Pressure Bar (SHPB) testing. The decrease in lattice parameter measurement of Ta-3 wt%W composition showed the alloying process has taken place during heat treatment procedure.

Tantalum tungsten alloys are composed of approximately 90-98% tantalum (Ta) and 2-10% tungsten (W), offering high strength, superior corrosion resistance, and excellent performance in high-temperature environments.

Tantalum tungsten powder is suitable for 3D printing due to its high melting point, exceptional strength and hardness, excellent corrosion resistance, biocompatibility, spherical particle shape for good flowability, and superior thermal and electrical conductivity.

Spherical powder, including tantalum tungsten alloy powder, is typically produced using advanced atomization techniques.

Gas Atomization:

- Process: Molten metal is sprayed into a chamber using a high-pressure inert gas (like argon or nitrogen), breaking the liquid into fine droplets.

- Formation: As the droplets cool and solidify in free fall, they form spherical particles.

- Advantages: Produces highly spherical and uniform particles, suitable for 3D printing and other precision applications.

Plasma Atomization:

- Process: A metal wire is fed into a plasma torch, where it is melted and then atomized by a stream of high-velocity gas.

- Formation: The molten droplets cool rapidly, forming spherical powder.

- Advantages: Produces very high-quality powder with excellent sphericity and purity.

Centrifugal Atomization:

- Process: Molten metal is ejected from a rotating disk or cup, breaking into droplets due to centrifugal force.

- Formation: The droplets solidify into spherical particles as they cool.

- Advantages: Suitable for producing powders with controlled particle size and distribution.

Electrode Induction Melting Gas Atomization (EIGA):

- Process: An electrode of the alloy is melted by induction heating, and the molten metal is then atomized using a high-pressure gas.

- Formation: The resulting droplets solidify into spherical particles.

- Advantages: Avoids contamination as there are no crucibles involved, ensuring high purity.

These methods are carefully controlled to produce powders with the desired particle size distribution and sphericity, essential for applications like 3D printing where uniformity and flowability of the powder are crucial.