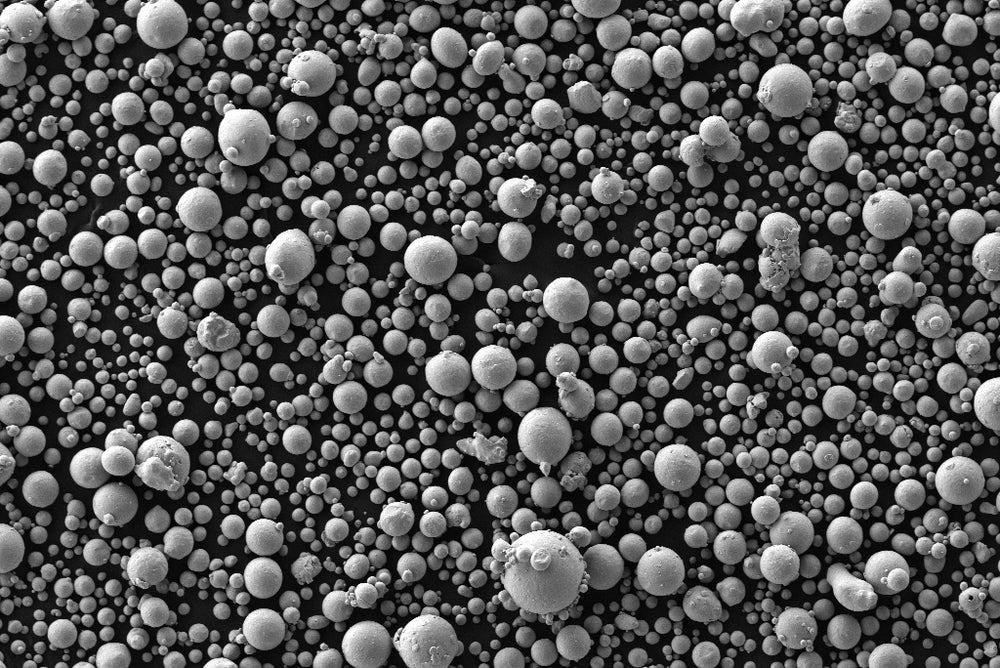

Gas-Atomized Spherical Tungsten Powder

High purity Tungsten Metal Spherical Powder, also know as UNS R07000 Tungsten Plasma-Spheroidized Powder, is widely used for additive manufacturing/3D printing applications. Tungsten Spheres is for sale at a competitive price.

Princeton Powder is a leading supplier of Tantalum Carbide refractory ceramic powder. Tantalum powders including Tantalum Nanoparticles, Tantalum Tungsten gas atomized powder, and Tantalum Disilicide powder are for sale in bulk.

Spherical Tungsten W Powder

Formula | Tungsten W |

Synonyms | spherical Tungsten particles, spherical Tungsten powders, Tungsten Powder, Tungsten thermal spray powder, Tungsten gas atomized powder |

Appearance | Black Powder |

Particle Size | 15-53 um, 45-105 um, can be customized upon request |

Melting Point | 3410 °C |

Density | 19.3 g/cm 3 |

Apparent Density | >9.5 g/cm3 |

Tap Density | >11.5 g/cm3 |

Description of Spherical Tungsten Powder

Spherical tungsten powder consists of uniformly round particles, produced primarily through atomization methods. It is known for its high density, melting point, and hardness, along with excellent thermal and electrical conductivity. This powder is used in high-performance applications such as high-density alloys, radiation shielding, and precision components in aerospace and defense. Its spherical shape enhances flowability and uniformity, making it suitable for advanced manufacturing processes. The powder is typically made by atomizing molten tungsten with high-pressure gas or water.

Princeton Powder is a leading supplier of Spherical tungsten powder. We have a range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. Tungsten powder is for sale in the USA.

Chemical Composition of Spherical Tungsten Powder

| Chemical Composition by ICP-AES | Wt % |

| W | ≥ 99.9 |

| Al | <0.002 |

| Si | <0.001 |

| Mg | <0.001 |

| Mn | <0.001 |

| Ni | <0.001 |

| As | <0.001 |

| Sn | <0.001 |

| Cu | <0.001 |

| Ca | <0.001 |

| Al | <0.001 |

| Mo | <0.001 |

| Gas Impurities | |

| O | ≤0.03 |

| N | ≤0.003 |

| C | ≤0.005 |

| P | ≤0.002 |

Tungsten Powder Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

High-Density Components: Used in aerospace, automotive, and defense industries for producing high-density components like counterweights and shielding materials. Its high density and strength make it ideal for applications requiring significant mass in a compact form.

Radiation Shielding: Employed in radiation shielding materials to protect against X-rays and gamma rays in medical and nuclear industries. Tungsten’s high density provides effective shielding.

Tooling and Cutting Tools: Used in manufacturing high-performance tooling and cutting tools, such as drills and inserts, due to its hardness and wear resistance.

3D Printing: In additive manufacturing, tungsten powder is utilized to print parts that require high density, hardness, and thermal stability. This includes custom aerospace components, high-density penetrators, and precision parts.

Electrical Contacts and Components: Applied in electrical contacts and components where high melting points and good conductivity are required.

Spherical Tungsten powder Reference

- In this study, radio frequency induction plasma was adopted to improve tungsten powder properties to meet the requirements of additive manufacturing process. After plasma spheroidization process operated, tungsten particles changed from irregular shape to uniform spherical shape. The average size and oxygen content of raw tungsten powders were both decreased, meanwhile, the laser absorption coefficient was increased by plasma spheroidization process. Furthermore, a series of tests were carried out for raw and spherical tungsten powders to investigate the influence of plasma spheroidization process on powder flowability evolution. The results displayed that, plasma spheroidized powders had a better comprehensive flowability, such as basic flow property, aerated flow property, compressibility, permeability and shear property, comparing to raw tungsten powders. In conclusion, plasma spheroidized tungsten powders met demands of additive manufacturing process very well.

The principal ferroalloys are ferromanganese, ferrochromium, ferromolybdenum, ferrotitanium, ferrovanadium, ferrosilicon, ferroboron, and ferrophosphorus. These are brittle and unsuitable for direct use in fabricating products, but they are useful sources of these elements for the alloy steels.

- Fe-Si (Iron-Silicon): Offers high magnetic permeability and low core loss.

- Fe-Ni (Permalloy): High permeability and low coercivity, ideal for magnetic shielding.

- Fe-Co (Iron-Cobalt): High saturation magnetization, used in high-performance applications.

- Fe-Si-Al (Sendust): Low core loss and high resistivity, suitable for high-frequency applications.

- Fe-Ni-Mo (Molypermalloy): Combines low coercivity with high permeability, used in precision inductors.

Main application processes for Soft Magnetic Powders:

- Powder Metallurgy: Compacting and sintering for cores in transformers and motors.

- Injection Molding: Molding complex shapes for sensors and inductors.

- Tape Casting: Creating thin magnetic sheets for transformers.

- Hot Pressing: High-pressure forming for high-performance components.

- Additive Manufacturing: 3D printing custom magnetic parts.

- Spray Forming: Applying magnetic coatings on surfaces.