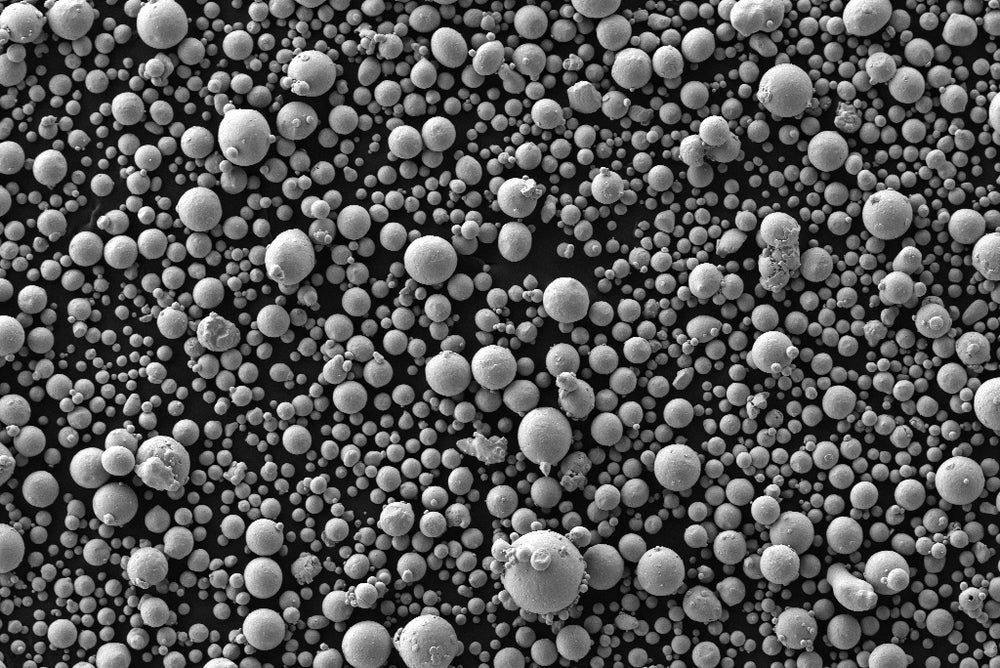

Spherical Tungsten Nickel Iron Alloy W-Ni-Fe Powder

Formula | Tungsten Nickel Iron Alloy W-Ni-Fe |

Synonyms | spherical W-Ni-Fe particles, spherical 97WNiFe powders, 95WNiFe Powder, 90WNiFe thermal spray powder, Invar 36 gas atomized powder |

Appearance | Black Powder |

Particle Size | 15-53 um, 45-105 um, can be customized upon request |

Purity | 99.9% min |

Low oxygen | < 300 ppm |

Hall Flow Rate | ≤ 8.0 s/50 g |

Tap density | ≥ 9.5 g/cm3 |

Related Products:

Spherical Stainless Steel 304L Powder (SS304l powder)

Spherical Titanium Ti-6Al-4V TC4 Powder

Spherical Nickel Based Inconel 625 Powder

Molybdenum Rhenium Alloy Mo-Re Spherical Powder

Spherical Tungsten Molybdenum Alloy W-Mo Powder

Spherical Tungsten Rhenium Alloy Powder (W-25Re)

Spherical Tungsten Nickel Copper W-6Ni-4Cu Powder

Description of Tungsten Nickel Iron Alloy W-Ni-Fe Spherical Powder

Tungsten nickel iron (W-Ni-Fe) is also known as tungsten heavy alloy or tungsten heavy metal alloy. Spherical Tungsten nickel iron (W-Ni-Fe) powder is a composite material combining tungsten, nickel, and iron.

It features high density, excellent hardness, and good thermal and electrical conductivity, with tungsten providing density and hardness, and nickel and iron improving machinability and strength. This powder is commonly used in high-performance applications such as counterweights, radiation shielding, and high-density alloys, and is typically produced through powder metallurgy or atomization methods.

Tungsten nickel iron (W-Ni-Fe) alloys are used to produce various products with different compositions tailored to specific applications. Here are some common products and their typical compositions:

- Composition: Typically 90-97% tungsten, 3-10% nickel, and 1-5% iron.

- Applications: Used in counterweights, ballasts, and balancing weights in aerospace, automotive, and industrial applications for their high density.

- Composition: About 85-95% tungsten, 5-10% nickel, and 2-10% iron.

- Applications: Employed in radiation shielding to protect against X-rays and gamma rays in medical and nuclear industries due to its high density and effective shielding properties.

- Composition: Generally 80-90% tungsten, 10-15% nickel, and 5-10% iron.

- Applications: Used in tooling, cutting inserts, and wear-resistant components where high hardness and toughness are required.

- Composition: Often around 90% tungsten, 7% nickel, and 3% iron.

- Applications: Utilized in military and aerospace for high-density penetrators and projectiles, leveraging the alloy’s density and strength.

Princeton Powder is a leading supplier of Tungsten nickel iron (W-Ni-Fe) powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. Tungsten heavy alloy powder is for sale at a competitive price.

Chemical Composition

Tungsten Nickel Iron Alloy Chemical Composition

| Chemical Composition: | Wt % |

| W | 90-97 |

| Ni | 1.0-9.0 |

| Fe | 1.0-9.0 |

| Mg | <0.005 |

| Mn | <0.004 |

| Sn | <0.001 |

| Cu | <0.003 |

| Ca | <0.001 |

| Gas Impurities | |

| O | ≤0.03 |

| N | ≤0.004 |

| C | ≤0.005 |

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

Counterweights and Ballasts: Used in aerospace, automotive, and industrial settings to balance and stabilize equipment, aircraft, and machinery due to their high density.

Radiation Shielding: Employed in medical and nuclear industries to shield against X-rays and gamma rays, providing effective protection due to the alloy’s high density.

Military and Aerospace Components: Utilized in armor-piercing projectiles, penetrators, and high-density components for defense and aerospace applications, leveraging the alloy’s strength and impact resistance.

Tooling and Cutting Tools: Applied in high-wear environments for machining inserts, dies, and cutting tools, benefiting from the alloy’s hardness and durability.

High-Density Weights: Used in various precision applications where high mass is required in a compact form, such as in vibration dampers and precision instruments.

Spherical Tungsten Nickel Iron Alloy W-Ni-Fe Powder Reference

- For the first time, a powder of W-5Ni-2Fe composition with spherical particles from 15 to 50 microns and a tungsten grain size from 0.5 to 3 microns was obtained using a new technological approach, developed by the authors, based on plasma spheroidization of powder granules made from nanoparticles synthesized in a plasma chemical process. The possibility of using the obtained spheroidized powder W-5Ni-2Fe in the process of selective laser melting (SLM) has been proved. The microstructure, physical, and mechanical characteristics of experimental samples made using SLM technology from the produced W-5Ni-2Fe powder have been studied. The results of the performed studies have shown that the microstructure of experimental samples is extremely dependent on the parameters of the SLM process. The precise choice of the SLM process mode made it possible to obtain a homogeneous structure of experimental samples of tungsten heavy alloy (WHA), with a tungsten grain size of about 1–2 microns, which is much smaller than the tungsten grain size in traditional heavy alloys.