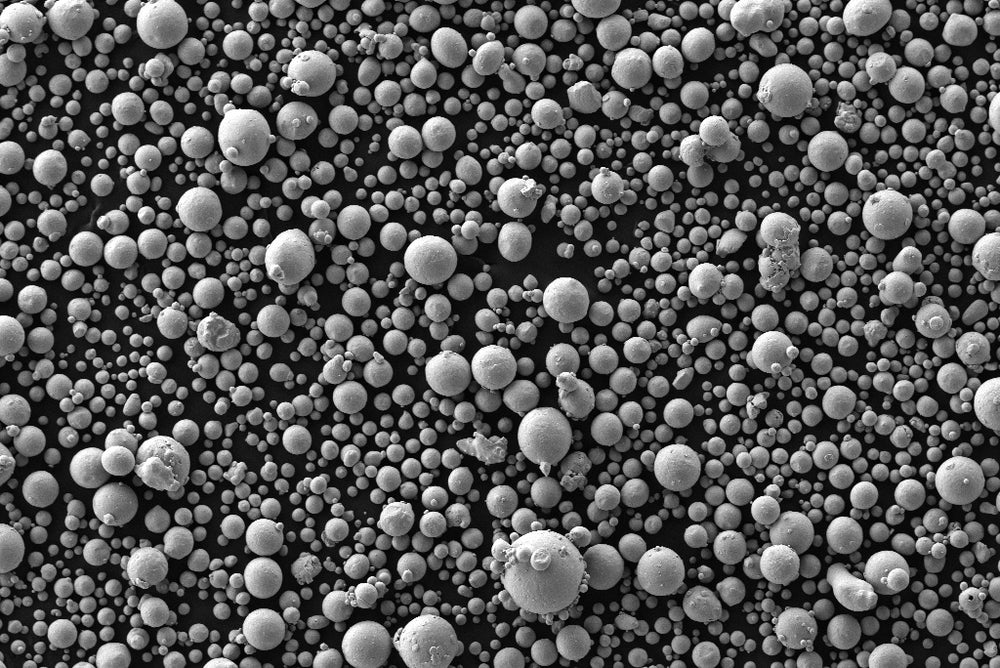

Spherical Titanium Ti-6Al-4V Eli Powder

Formula | Titanium Grade 23, Ti 6Al 4V Eli |

Synonyms | Spherical Ti-6Al-4V Eli particles, Spherical Ti Gr23 powders, Ti-6Al-4V Eli Titanium Powder, Ti 6Al 4V Eli thermal spray powder, Ti 6Al 4V Eli gas atomized powder |

Appearance | Black Powder |

Particle Size | 15-53 um, 45-105 um, can be customized upon request |

Melting Point | 1660 °C |

Density | 4.5 g/cm 3 |

Apparent density | 2.51 g/cm3 |

Flow rate | 26s |

Description of Titanium Ti-6Al-4V Eli Powder

Titanium Ti-6Al-4V ELI Powder is a highly refined version of the Ti-6Al-4V alloy, where “ELI” stands for “Extra Low Interstitials.” This powder consists of fine particles of the titanium alloy composed of approximately 90% titanium, 6% aluminum, and 4% vanadium, with significantly reduced levels of interstitial impurities like oxygen, nitrogen, and carbon.

The Titanium Ti grade 23 powder particles, often spherical and ranging from a few microns to 150 microns in size, are highly pure and biocompatible. This powder is widely used in medical implants, aerospace components, and 3D printing, where strength, corrosion resistance, and precision are critical.

Princeton Powder is a leading supplier of Ti grade 23 spherical powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. Titanium Ti-6Al-4V ELI Powder is for sale at a competitive price.

Chemical Composition

Spherical Titanium Powder Grade 23 Chemical Composition

| Grade | Al | V | Fe | C | N | H | O |

| TC4 | 5.5~6.75 | 3.5~4.5 | ≤0.30 | ≤0.08 | ≤0.05 | ≤0.015 | 0.08~0.15 |

| TC4ELI | 5.5~6.5 | 3.5~4.5 | ≤0.25 | ≤0.08 | ≤0.03 | ≤0.012 | 0.08~0.13 |

| Element, Mass Fraction(Wt.%) | |||||||

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

- Medical Implants: Due to its biocompatibility, high strength, and low modulus of elasticity, Ti-6Al-4V ELI powder is widely used in the production of orthopedic implants and dental devices.

- Aerospace Components: It is also used in additive manufacturing and metal injection molding for aerospace components requiring high strength and corrosion resistance.

- 3D Printing: The powder form is particularly suited for powder bed fusion and other additive manufacturing processes, enabling the creation of complex, precise geometries.

Spherical Titanium Ti-6Al-4V Eli Powder Reference

Microstructure and mechanical properties of Titanium grade 23 produced by selective laser melting

- Selective laser melted Titanium grade 23 was characterized by low porosity, relatively large surface roughness and pronounced surface texture (i.e. surface grooves orientation). The band/layer microstructure was built of mixed α and β phases. The as printed structure exhibited very high compressive residual stresses with strong anisotropy (i.e., − 512 ± 17 MPa and − 282 ± 14 MPa along the laser scanning direction and along the transverse direction, respectively) and strong fiber crystallographic texture.

Ti-6Al-4V Grade 23 and Titanium Grade 5 (also known as Ti-6Al-4V Grade 5) are both titanium alloys with 6% aluminum and 4% vanadium, but they differ primarily in their impurity levels and specific applications:

Grade 23 (Ti-6Al-4V ELI): “ELI” stands for “Extra Low Interstitials,” meaning this grade has lower levels of impurities such as oxygen, nitrogen, carbon, and iron. This results in improved ductility, fracture toughness, and biocompatibility.

Grade 5 (Ti-6Al-4V): Has slightly higher levels of these interstitial elements, making it less ductile but stronger and harder.

Grade 23: Due to its enhanced purity and mechanical properties, Grade 23 is primarily used in medical applications like implants, where biocompatibility and high fracture toughness are critical.

Grade 5: This grade is widely used in aerospace, automotive, and industrial applications due to its excellent strength-to-weight ratio, corrosion resistance, and overall mechanical performance.

Ti6Al4V ELI (Grade 23) is a titanium alloy with aluminium and vanadium. It is a purer version of the standard TA6V alloy. Interstitial element contents (iron, oxygen and carbon) are strictly controlled and limited during the fusion process.

The essential difference between Ti6Al4V ELI (grade 23) and Ti6Al4V (grade 5) is the reduction of oxygen content to 0.13% (maximum) in grade 23. This confers improved ductility and fracture toughness, with some reduction in strength.