Titanium Based Ti-6Al-4V (TC4) Spherical Powder

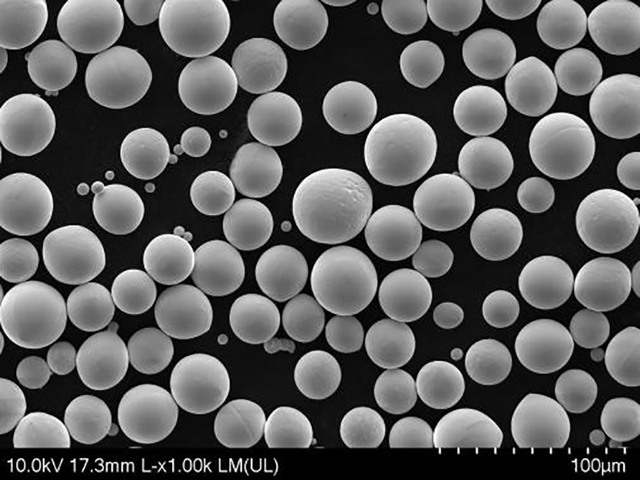

Titanium-based Ti-6Al-4V (TC4) spherical powder is a high-performance material widely used in additive manufacturing, aerospace, and biomedical applications. Known for its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility, TC4 powder ensures superior part quality and durability. Produced via advanced atomization techniques, this powder offers high sphericity, smooth flowability, and consistent particle size distribution for optimal 3D printing results. Ideal for selective laser melting (SLM), electron beam melting (EBM), and other powder bed fusion technologies.

Titanium Based Ti-6Al-4V (TC4) Spherical Powder

Formula | Titanium Ti-6Al-4V, Titanium Ti-6Al-4V ELI |

Purity | TC4 |

Synonyms | Titanium 6AL-4V, Titanium Grade 5, Ti-6Al-4V, Ti 6-4, Titanium Grade 23,Titanium 6AL-4V Eli spherical powder |

Appearance | Silvery-gray powder |

Melting Point | 1660°C |

Boiling Point: | N/A |

Density | 4.43g/cm3 |

Tensile Strength | 950-1000 MPa |

Description of Titanium Based Ti-6Al-4V (TC4) Spherical Powder

Ti-6Al-4V (TC4) spherical powder is a titanium alloy primarily composed of titanium (approximately 90%), aluminum (6%), and vanadium (4%). Ti-6Al-4V (TC4) stands out in 3D printing for its high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. Compared to materials like stainless steel or aluminum alloys, TC4 offers superior strength and durability with reduced weight. Its spherical powder form ensures smooth flow and uniform packing density during printing, resulting in precise parts with consistent mechanical properties. Ti-6Al-4V (TC4) is widely used in aerospace, medical, and industrial sectors for manufacturing lightweight, strong, and durable components.

Princeton Powder is a leading supplier of Ti-6Al-4V (TC4) spherical powder and Ti-6Al-4V Eli spherical powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. With our expertise, we are confident in supporting your projects effectively and provide you with reliable solutions.

Spherical Titanium Based Ti-6Al-4V (TC4) Powder Chemical Composition

| Grade | Al | V | Fe | C | N | H | O |

| TC4 | 5.5~6.75 | 3.5~4.5 | ≤0.30 | ≤0.08 | ≤0.05 | ≤0.015 | 0.08~0.15 |

| TC4ELI | 5.5~6.5 | 3.5~4.5 | ≤0.25 | ≤0.08 | ≤0.03 | ≤0.012 | 0.08~0.13 |

| Element, Mass Fraction(Wt.%) | |||||||

Spherical Titanium Based Ti-6Al-4V (TC4) Powder Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Benefits/Application of Spherical Titanium Based Ti-6Al-4V (TC4) Powder

Titanium Grade 5 Spherical powder finds various applications, particularly in additive manufacturing (3D printing)

- Enhanced Flowability: 3D printing processes. Selective Laser Melting (SLM) or Electron Beam Melting (EBM)

- High Strength-to-Weight Ratio: Ideal for lightweight, strong parts.

- Corrosion Resistance: Suitable for aerospace, marine, and medical applications.

- Biocompatibility: Used in medical implants and surgical instruments.

- Versatility: Widely applicable across aerospace, automotive, and consumer industries

Titanium Based Ti-6Al-4V (TC4) Spherical Powder Reference

Fabrication of spherical Ti–6Al–4V powder for additive manufacturing by radio frequency plasma spheroidization and deoxidation using calcium

- Commercial hydride-dehydride Ti–6Al–4V powder was used as raw material to fabricate high-quality spherical Ti–6Al–4V powder by radio frequency (RF) plasma spheroidization and calcium deoxidation in this work.

Titanium alloy powder, like Ti-6Al-4V (TC4), is essential in 3D printing for producing lightweight, strong components across aerospace, medical, automotive, and consumer industries.

Ti-6Al-4V, Titanium Grade 5 alloy (UNSR56400) is the most widely used titanium grade. It is a two phase α+βtitanium alloy, with aluminum as the alpha stabilizer and vanadium asthe beta stabilizer.

Titanium Ti-6Al-4V rep- resents an alloy containing aluminum (Al) of 6wt% and Vanadium (V) of 4wt%. For aircraft engines, titanium alloys stronger than pure titanium are used for their light weight, high strength (high specific strength) and heat resistance properties.