Stainless Steel 316L Powder (SS 316L Spherical Powder)

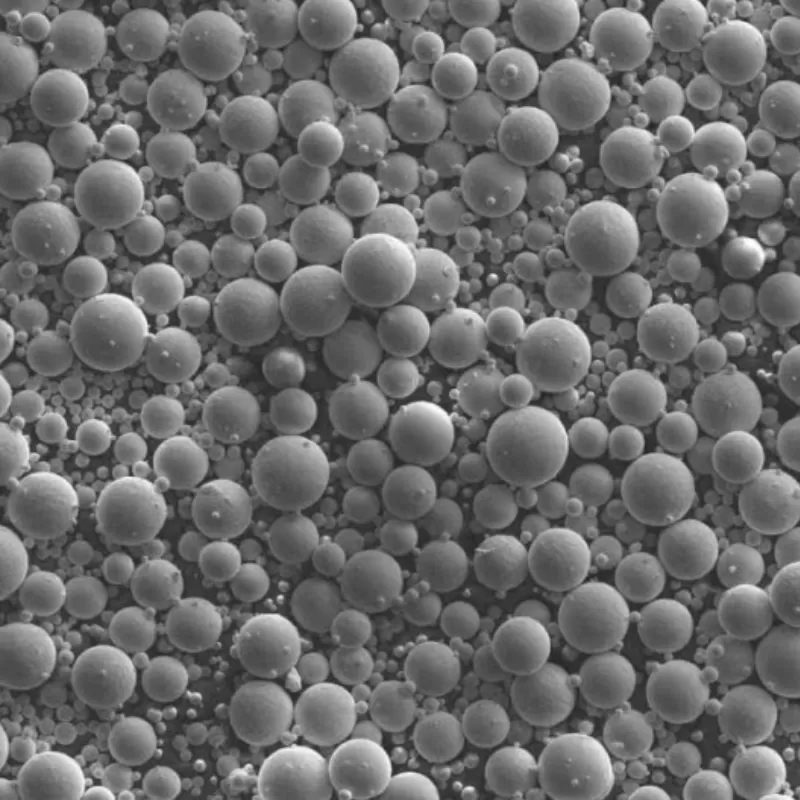

AISI SS 316L Metal Powder is a Austenitic Stainless Steel Powder, which is widely used for 3D Printing. Gas-Atomized SS 316L Powder and Plasma-Atomized Stainless Steel 316L Powder are widely applied to additive manufacturing/3d printing including Laser Powder Bed Fusion and Electron Beam Melting process. High-quality 316L Stainless Steel Spherical Powder for 3D Printing (LPBF/MIM). ASTM F138 certified, low oxygen (<300ppm), excellent flowability. Medical/Aerospace grade.

Princeton Powder is a leading supplier of SS 316L gas atomized powder.Stainless Steel metal powders including 304L stainless steel powder, 410L stainless steel powder, and 430L stainless steel powder are for sale in bulk.

Stainless Steel 316L Spherical Powder

Formula | Stainless Steel 316L |

Synonyms | SS 316L spherical particles,SS 316L spherical powders, Stainless Steel Powder, AISI 316L thermal spray powder, AISI 316L gas atomized powder |

Appearance | Black Powder |

Particle Size | 15-45 um,15-53 um, 45-105 um, can be customized upon request |

Melting Point | 1375 – 1400°C |

Density | 7.9 g/cm 3 |

Tap Density | 5.0 g/cm³ |

Apparent density | 2.7 g/m3 |

Description of Stainless Steel 316L Spherical Powder

Stainless steel 316L is a low-carbon version of stainless steel 316, known for its corrosion resistance, especially in environments where exposure to chemicals and saltwater is common.

SS 316L spherical powder, which is advantageous for additive manufacturing processes such as powder bed fusion (like selective laser melting or electron beam melting). Spherical particles flow more easily and evenly during processing, leading to better consistency in the printed parts.

Princeton Powder is a leading supplier of AISI 316L metal powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. With our expertise, we are confident in supporting your projects effectively and provide you with reliable solutions.

316L stainless steel powder Chemical Composition

Chemical Composition (wt%) | ||||||||||

Item | Fe | C | Mn | Si | Ni | Cr | Mo | V | W | Al |

316L | Bal | – | ≤2.0 | ≤1.0 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | – | – | – |

Mg | Cu | Ti | Nb | Zr | P | S | Co |

|

| |

– | – | – | – | – | – | – | – |

|

| |

Oxygen≤800 ppm; Nitrogen≤600 ppm

316L metal powder Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

SS316l Powder Applications

- Additive Manufacturing: Used in metal 3D printing to create parts directly from digital designs.

- Surface Coatings: Applied as a spray coating to provide corrosion resistance and enhance surface properties.

- Metal Injection Molding (MIM): Used as feedstock for producing small, complex parts in industries such as medical devices and automotive.

- Powder Metallurgy (P/M)

- Sintered porous metal filter

- Polyester and nylon fiber production

- Surface Coating / Hardfacing

- Paint Additives

Spherical Stainless Steel 316L Powder Reference

- 316L austenitic stainless steel is one of the most widely used metal materials, which has excellent properties such as high corrosion and oxidation resistance, moderate strength, and good plasticity [28], [29], [30], [31]. So far, many researchers have been devoted to the study of additive manufacturing of 316L SS, especially those about the LPBF technology.

Stainless steel 316 has a maximum carbon content of 0.08%, while stainless steel 316L has a maximum carbon content of 0.03%. The lower carbon content in 316L reduces the risk of sensitization (loss of corrosion resistance in welded areas) and enhances its corrosion resistance in various environments.

Stainless steel powder is suitable for 3D printing because it allows for precise and complex shapes to be produced directly from digital designs using techniques like selective laser melting or electron beam melting. This powder form ensures uniform particle size and flowability, essential for achieving high-quality, durable metal parts with excellent mechanical properties.

Stainless steel powder itself is not flammable under normal conditions. However, like any finely divided metal powder, it can pose a fire hazard if dispersed in air and exposed to an ignition source. The main concern is not the powder igniting spontaneously but rather the potential for combustion if exposed to a strong enough heat source, such as in a fire situation or during certain manufacturing processes.