Stainless steel powder for additive manufacturing

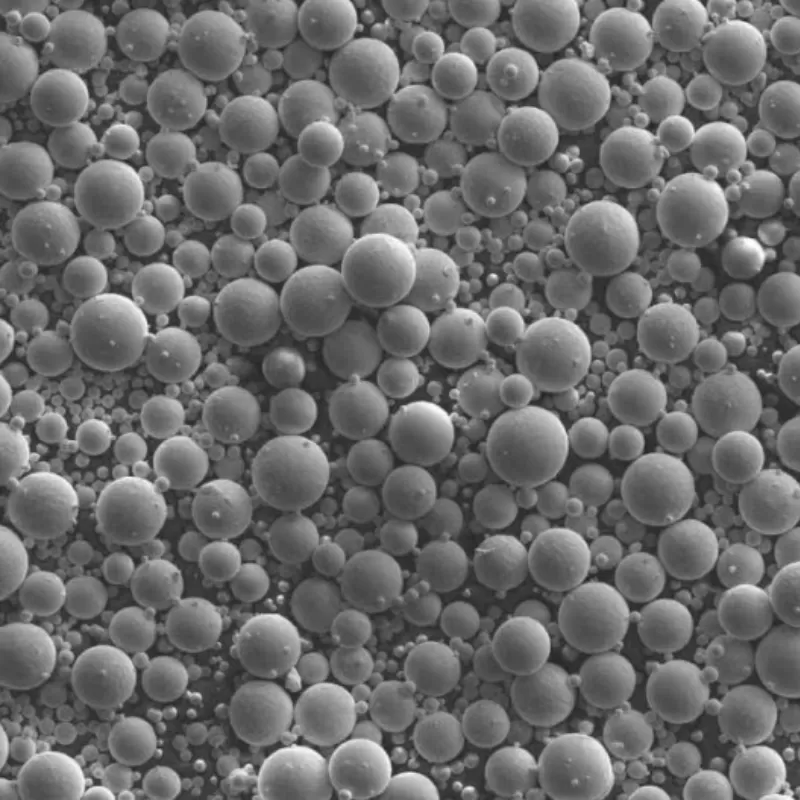

High-quality stainless steel powder for 3D printing and additive manufacturing. Our spherical stainless powder (15-53μm) ensures excellent flowability and uniform particle size for precision printing. Available grades: 316L stainless steel powder, 316 stainless steel powder, 410L stainless steel powder, 430L stainless steel powder, and 434L stainless steel powder. Ideal for metal AM applications, laser sintering (SLS), and powder bed fusion (PBF). Competitive prices, bulk availability, and global shipping. For sale now—inquire for pricing and specifications!

Spherical Stainless Steel 304L Powder (SS304L Powder)

Formula | Stainless Steel 304L |

Synonyms | Spherical SS 304L particles, SS 304L spherical powders, Stainless Steel 304L Powder, AISI 304 thermal spray powder, AISI 304 gas atomized powder |

Appearance | Black Powder |

Particle Size | 0-45 um, 45-105 um, can be customized upon request |

Melting Point | 1400 – 1450°C |

Density | 7.9 g/cm 3 |

Tap Density | 5.0 g/cm³ |

Apparent density | 2.7 g/m3 |

Description of Spherical Stainless Steel 304L Powder

Stainless Steel 304L contains approximately 18% chromium, 8% nickel, 2% manganese, 1% silicon, and ≤0.03% carbon, with additional trace elements, offering excellent corrosion resistance and good mechanical properties, including enhanced weldability..

SS 304L Stainless Steel alloy spherical powder is crucial for additive manufacturing (AM) techniques like selective laser melting (SLM) or powder bed fusion (PBF). Spherical particles ensure uniform flowability and packing density, which are critical for achieving high-quality printed parts.

Princeton Powder is a leading supplier of AISI 304L spherical powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. With our expertise, we are confident in supporting your projects effectively and provide you with reliable solutions.

Spherical Stainless Steel Powder types

Austenitic SS powder (304, 316L)

Martensitic SS powder (420, 440C)

Duplex SS powder (2205)

Precipitation-hardening powder (17-4PH, 15-5PH)

Spherical Stainless Steel 304L Powder production method

Gas atomized stainless steel powder

Water atomized metal powder

Plasma rotating electrode (PREP) powder

Electrolytic stainless powder

Stainless steel metal powder Chemical Composition

Chemical Composition (wt%) | ||||||||||

Item | Fe | C | Mn | Si | Ni | Cr | Mo | V | W | Al |

SS 304L | Bal | – | ≤2.0 | ≤1.0 | 8.0~12.0 | 18.0~20.0 | – | – | – | – |

Mg | Cu | Ti | Nb | Zr | P | S | Co |

|

| |

– | – | – | – | – | – | – | – |

|

| |

Oxygen≤800 ppm; Nitrogen≤600 ppm

Stainless powder Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

Additive Manufacturing: Aerospace brackets, biomedical devices

Metal Injection Molding: Firearm components, watch gears

Thermal Spray: Corrosion-resistant coatings for oil/gas

Laser Cladding: Turbine blade repair

Catalysts: Porous SS powder for chemical processing

Spherical Stainless Steel 304L Powder Reference

Spheroidisation of Stainless Steel Powder for Additive Manufacturing

- In additive manufacturing, powder characteristics play an important role in terms of flowability and densification, which can be improved by the use of spherical powders. Spherical AISI 304 stainless steel powders were produced by plasma spheroidization, and the efficiency of the spheroidisation process was evaluated. The spheroidisation process resulted in 93% efficiency with a decrease of fine particles (<63 µm) by 22%, while the all the flowability parameters of the powder improved significantly.

The distinguishing feature of 304L compared to 304 is its lower carbon content (typically 0.03% maximum), which minimizes carbide precipitation during welding and reduces the risk of corrosion in certain environments.

Stainless Steel 304 typically contains about 18% chromium, 8% nickel, and ≤0.08% carbon, while Stainless Steel 316 includes roughly 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, enhancing its corrosion resistance properties, especially in harsh environments.

The choice between Stainless Steel 304 and 316 depends on the specific application and environmental conditions:

Stainless Steel 304:

Advantages: Good general corrosion resistance, particularly in less aggressive environments such as rural atmospheres, food processing facilities, and indoor applications.

Disadvantages: Less resistant to chloride environments and may corrode over time in marine or coastal environments.

Stainless Steel 316:

Advantages: Higher corrosion resistance, especially against chlorides and acids. It is suitable for marine environments, coastal areas, and applications involving exposure to chemicals or saltwater.

Disadvantages: Generally more expensive than 304 due to the addition of molybdenum.

Decision Factors:

Choose 316 for superior resistance in aggressive environments.

304 is typically more cost-effective unless the enhanced corrosion resistance of 316 is necessary.