Rhenium Powder (Re Spherical Powder)

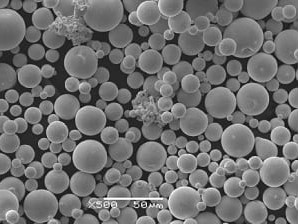

Princeton Powder is a worldwide manufacturer of high-purity rhenium metal powder. Our rhenium spherical powder (≥99.99%) is designed for applications demanding exceptional thermal stability and strength. With customizable particle sizes, typically ranging from 15 to 45 microns, it offers excellent flowability for precision manufacturing processes like 3D printing. The ultra-low oxygen content (<1000 ppm) ensures minimal oxidation, maintaining material integrity even at high temperatures. With a sphericity level of ≥0.95, this powder provides optimal performance in powder-based techniques such as laser sintering and metal injection molding. It is ideal for industries like aerospace, electronics, and catalysis where reliability and efficiency are paramount.

We provide a wide range of rhenium powder products including Molybdenum Rhenium Mo-Re Spherical Powder and Tungsten Rhenium W-Re spherical Powder. Our rhenium powder is for sale at a competitive price in the USA.

Formula | Rhenium Re |

CAS Number | 7440-15-5 |

Purity | 99.95% min, 99.99%, 99.999% |

Synonyms | Rhenium Microns Powder, Re spherical powder, Rhenium thermal spray powder, Rhenium Spherical Powder |

Particle Sizes | 0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm |

Appearance | Gray metal powder |

Melting Point | 3180°C |

Boiling Point | 5596°C |

Spherification rate | >95% |

Tap Density | >10.5 g/cm3 |

Description of Rhenium Powder

Rhenium spherical powder is a specialized material that features rhenium particles shaped in a spherical form, typically used in high-performance applications due to rhenium’s exceptional properties. Rhenium is known for its high melting point (3,180°C), good mechanical strength at high temperatures, and resistance to wear and corrosion.

Chemical Composition of Spherical Re Powder

Element | 4N Grade | 5N Grade | Element | 4N Grade | 5N Grade | ||

K | 0.0005 | 0.00005 | Mg | 0.0001 | 0.00001 | ||

Na | 0.0005 | 0.00005 | Ti | 0.0001 | 0.00001 | ||

Ca | 0.0005 | 0.00005 | Sb | 0.0001 | 0.00001 | ||

Mo | 0.0005 | 0.00005 | Be | 0.0001 | 0.00001 | ||

W | 0.0005 | 0.00005 | Cd | 0.0001 | 0.00001 | ||

Fe | 0.0005 | 0.00005 | Ni | 0.0001 | 0.00001 | ||

Co | 0.0005 | 0.00005 | Cr | 0.0001 | 0.00001 | ||

Al | 0.0001 | 0.00001 | Pb | 0.0001 | 0.00001 | ||

Mn | 0.0001 | 0.00001 | Ba | 0.0001 | 0.00001 | ||

Cu | 0.0001 | 0.00001 | Zn | 0.0001 | 0.00001 | ||

Pt | 0.0001 | 0.00001 | Sn | 0.0001 | 0.00001 | ||

O | 0.08 | 0.06 |

|

|

| ||

Particle Size | 0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm, or Customized. | ||||||

Physical Properties | |||||||

Apparent Density (g/cm3) | Tap Density (g/cm3) | Hall Flow Rate (s/50g) | |||||

>9.50 | >10.5 | <10.0 | |||||

Spherical Rhenium (Re) Powder – Key Parameters

- Particle Size & Distribution: D10, D50, D90 (µm): (e.g., 15–45 µm, 45–106 µm); Mesh Size: (e.g., -325 mesh, -400 mesh); Nanopowder Options: (e.g., 50–200 nm)

- Purity & Composition: Purity: 99.9% (3N), 99.99% (4N), 99.995% (4N5)

- Impurity Limits: O < 500 ppm, C < 100 ppm, Metallic impurities < 200 ppm

- Morphology & Structure: Sphericity: ≥95% (gas-atomized), improved flowability

- Production Method: Gas Atomization (Ar/He): High sphericity, low oxygen; Plasma Rotating Electrode Process (PREP): Ultra-clean, satellite-free

Application of Spherical Rhenium Powder

Rhenium is used in aerospace for jet engine components and gas turbines due to its excellent thermal stability and oxidation resistance. In additive manufacturing, its spherical powder form ensures good flowability and precision in 3D printing complex metal parts. As a catalyst in petrochemical refining, rhenium resists deactivation at high temperatures while enhancing catalytic performance. In electronics and semiconductors, it is valued for its electrical properties, making it useful in high-temperature applications like filaments and contacts. Additionally, rhenium’s ability to withstand radiation and extreme temperatures makes it suitable for nuclear reactors.

Spherical Rhenium Powder Reference

Consolidation methods for spherical rhenium and rhenium alloys

- The development of high density spherical rhenium and spherical tungsten-rhenium powders has enabled the use of advanced consolidation techniques for the manufacture of refractory metal components. The investigated consolidation techniques are powder metal injection moulding (PIM) and vacuum plasma spraying (VPS); both produce net shape components. The required particle size distributions for these applications vary. VPS uses a large powder particle size (<44 μm) while PIM requires a fine particle size (<20 μm). The major advantages of spherical powders over traditional powders in plasma spraying are the high density of the powder particles and its good flow characteristics.

FAQ Rhenium Metal Powder

Q1. What is spherical rhenium powder used for?

Spherical Re powder is critical for:

Additive Manufacturing (3D Printing): Laser powder bed fusion (LPBF) of rocket nozzles, turbine blades.

Thermocouples: Re-W alloys for ultra-high-temperature measurements (>2000°C).

Aerospace Coatings: Plasma-sprayed coatings for wear/heat resistance.

Electronics: Contacts in extreme environments.

Q2. Why choose spherical over irregular Re powder?

Better flowability for automated AM processes.

Higher packing density (up to 60% tap density vs. 40% for irregular).

More uniform sintering with fewer voids.

Q3. How is spherical Re powder produced?

Gas Atomization: Molten Re is atomized with inert gas (Ar/He).

Plasma Rotating Electrode (PREP): Produces satellite-free powders.

Chemical Reduction: For nano-sized Re powders (<100nm).

Q4. What particle sizes are typical?

AM (LPBF): 15–45 µm.

Thermal Spray: 45–106 µm.

Nano Applications: 50–200 nm.