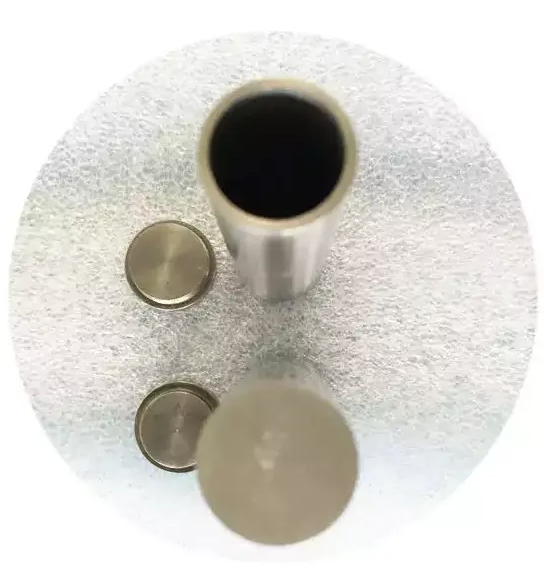

Tungsten Crucible (Tungsten Welding Crucible, Seamless Crucible)

Princeton Powder is a top provider of premium tungsten crucibles. We supply cylindrical, rectangular, square, and round-bottom crucibles, manufactured through either forging or welding processes. Our seamless tungsten crucibles are renowned for their superior mechanical strength, heat resistance, and corrosion protection, making them perfect for challenging high-temperature environments. Available in sizes ranging from 2 ml to 1,000 ml, these crucibles can also be tailored to meet specific customer needs.

We offer a broad selection of refractory metal crucibles, including molybdenum, zirconium, niobium, and tantalum crucible. Our tungsten crucibles are available at competitive prices.

Material | Tungsten Crucible, W |

CAS Number | 7440-33-7 |

Purity | 99.95% min |

Standard | ASTM B777 |

| Density | 19.28 g/cm3 |

Melting Point | 3422 ℃ |

Shape | Straight Wall, Cylindrical, Rectangular or Square, Custom-shaped |

Dimensions | 10-500 mm OD x 10-600 mm L |

Capacity | 2 ml-1,000 ml |

| Type | Seamless or welding crucible |

Description of Tungsten Crucible

Standard Dimensions of Tungsten Crucible

| OD (mm) | Wall Thickness (mm) | Height(mm) |

|---|---|---|

| 10 ~ 30 | 1.0 ~ 3 | 20 ~ 50 |

| 30 ~ 50 | 2~ 10 | 20 ~ 100 |

| 50 ~ 100 | 3 ~ 15 | 30 ~ 150 |

| 100 ~ 150 | 3 ~ 15 | 30 ~ 500 |

| 150 ~ 200 | 5 ~ 20 | 30 ~ 500 |

| 200 ~ 300 | 8 ~ 20 | 30 ~ 500 |

| 300 ~ 400 | 8 ~ 30 | 40 ~ 500 |

| 400 ~ 450 | 8 ~ 30 | 50 ~ 500 |

| 450 ~ 620 | 8~ 30 | 50 ~ 500 |

| Dimensions can be customized per the drawing | ||

Features and Application

High Melting Point: Perfect for melting metals with high melting thresholds such as titanium and zirconium.

Outstanding Corrosion Resistance: Withstands degradation from acids, bases, and harsh chemicals.

Biocompatibility: Suitable for applications that require both biocompatibility and resistance to corrosion.

Thermal Stability: Well-suited for managing corrosive substances in high-heat chemical processes.

Mechanical Strength: Frequently used in aerospace components due to its durability.

Essential factors for selecting the right Tungsten Crucible

Purity Level

Verify the purity level of the tantalum material used in the crucible, particularly for specialized applications like electronics.

Size and Capacity

Confirm the size and capacity requirements for your application

Material Compatibility

Ensure that the material does not chemically react with tungsten and confirm that tungsten itself meets the physical properties required for the working conditions, such as melting point and reactivity with the environmental atmosphere.

Customized Requirements

Provide detailed customization requirements, including drawings, working conditions, and product application information.