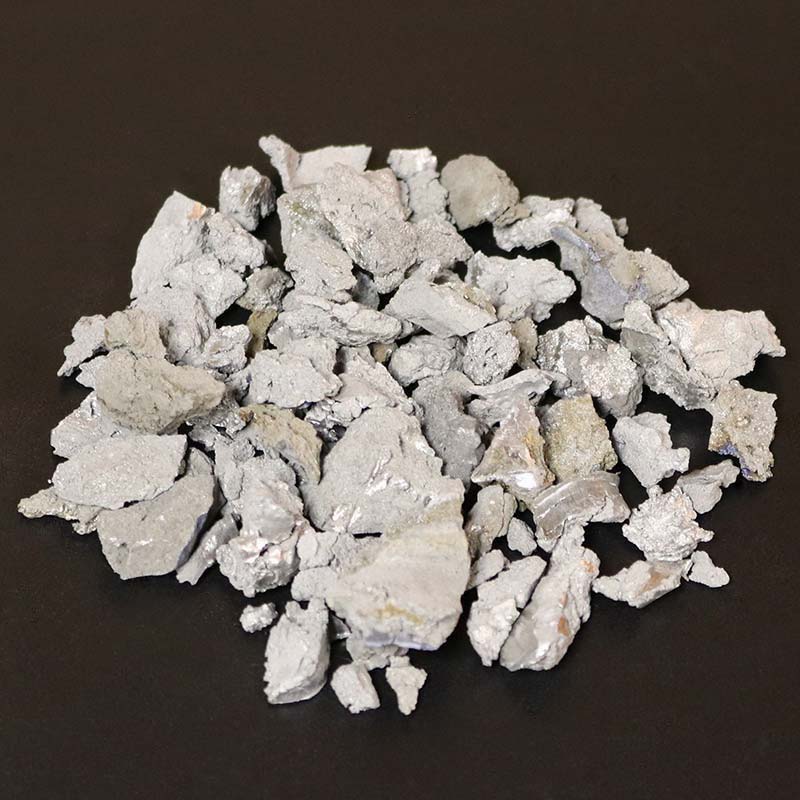

High-Purity Hafnium Sponge, Hf Granule

Hafnium sponge is typically produced through a reduction process, often utilizing methods such as the Kroll process or magnesium reduction of hafnium tetrahalides or hafnium oxide (HfO₂). The reduction results in high-purity hafnium metal, which is then further processed into a porous, granular form. This process creates hafnium sponge with a high surface area and porosity, making it ideal for specific industrial applications. The material is usually subjected to additional treatments like vacuum or inert gas atmospheres to ensure it retains its purity and desired characteristics.

Princeton Powder is a leading supplier of Hafnium Hf sponge. We specialize in a comprehensive range of Hafnium Hf products. Hafnium Hf sponge, Hafnium Hf powder, and Hafnium Hf crystal bar is for sale at a competitive price.

Granular Hafnium Sponge, Fine Hf Sponge

| Chemical Name | Hafnium, Hf |

| Appearance | Silver gray sponge |

| Assay Percent Range | 99.6%, Zr nominal 3% (Metals basis excluding Zr) |

| Density | 13.09 g/cm3 |

| Melting Point | 2227°C |

| Boiling Point | 4602°C |

| Synonyms | High-Purity Hafnium Sponge, Coarse Hafnium Sponge Powder, Industrial-Grade Hafnium Sponge, Oxygen-Scavenging Hafnium Sponge |

Hafnium sponge is a highly pure, coarse powdered or granular form of hafnium metal with exceptional porosity, making it ideal for a variety of industrial applications. Available in standard particle sizes ranging from 3mm to 25mm, and with custom sizes available upon request, this versatile material is commonly used as an oxygen scavenger and in catalytic processes due to its reactive properties. Additionally, our product line includes other high-performance sponge powders, such as palladium sponge, platinum sponge, and titanium sponge, each offering unique characteristics for specialized uses in aerospace, electronics, and chemical industries.

Description of Industrial-Grade Hafnium Sponge

Hafnium Hf sponge is a porous, metallic form of hafnium produced by reducing hafnium tetrachloride with magnesium in the Kroll process. It appears as a metallic gray, spongy material with high purity and lower density than solid hafnium. Hafnium pellet is reactive at high temperatures, particularly with oxygen, nitrogen, and hydrogen. Hafnium granule is primarily used in the nuclear industry for control rods, in superalloys, and in aerospace applications where high melting points and corrosion resistance are critical. It serves as an intermediate product for manufacturing various high-performance materials.

Chemical Composition of Oxygen-Scavenging Hafnium Sponge

Hf+Zr>99.6%,

Zr<1%, Zr≤0.2%/0.3%/0.5%

Applications

Oxygen Getters: Hafnium sponge is widely used as an oxygen scavenger in high-temperature environments, such as in the aerospace and nuclear industries. Its high reactivity with oxygen helps in creating oxygen-free environments.

Catalysis: Due to its high surface area, hafnium sponge is used as a catalyst or catalyst support in various chemical processes, including those in petroleum refining and chemical manufacturing.

Aerospace: In aerospace applications, hafnium sponge is utilized for its excellent high-temperature stability and resistance to corrosion, making it valuable in engine components and high-performance alloys.

Nuclear Applications: Hafnium’s neutron-absorbing properties make it suitable for use in nuclear reactors, particularly in control rods where it helps regulate the rate of fission reactions.

Electronics: In advanced electronics and thin-film coatings, hafnium sponge is used due to its high melting point and unique electrical properties.

High-Temperature Alloys: Hafnium sponge is often used in producing high-performance alloys that are used in environments requiring extreme heat resistance, such as turbine blades and other components in gas turbines.

Hafnium Sponge, Hf Granule Reference

Purification of Hafnium metal sponge by electron beam melting

- Purification of Hf sponge with 97.931 mass % by electron beam melting (EBM) has been carried out and the removal behavior of various impurity elements (metallic and non-metallic) has been examined. The influence of factors and process parameters of EBM, determining refining processes, was studied. Many metallic impurities (such as Cr, Si, Ti, Zn, Cu, Ni, etc.) in the melted Hf were removed to very low levels. Then the purity of Hf were improved to nearly 99.07% after 11 min of EBM with 11.25 kW beam power and oxygen concentration was decreased from nearly 300 ppm to less than 10 ppm. The results from a microstructural study of the samples after the electron beam processing are presented. The results obtained show high efficiency of the EB melting of the Hf sponge.

Hafnium Sponge FAQ

How should Hafnium Sponge be stored? Hafnium sponge should be stored in a dry, controlled environment to prevent oxidation and maintain its purity. It should be kept in sealed containers to avoid exposure to moisture and air.

Is Hafnium Sponge safe to handle? While hafnium sponge is generally safe to handle, precautions should be taken to avoid inhalation of fine particles. Proper handling procedures, including personal protective equipment (PPE) such as gloves and masks, should be followed.

How is Hafnium Sponge produced? Hafnium sponge is produced through a reduction process where hafnium metal is extracted from its ores or compounds, then processed into a coarse, porous form that enhances its reactivity and surface area.

What industries use Hafnium Sponge? Hafnium sponge is primarily used in aerospace, nuclear, electronics, and chemical industries, particularly in applications requiring high heat resistance, chemical stability, and efficient oxygen scavenging.