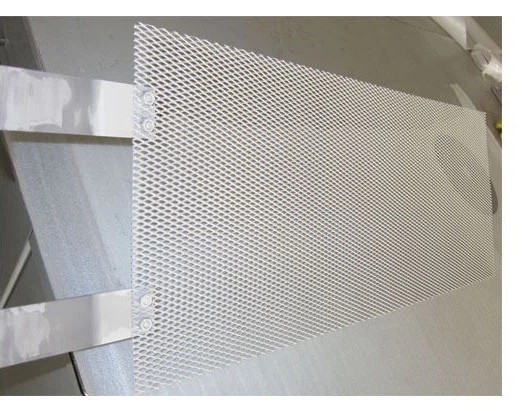

Platinum-Coated Titanium Mesh Anode

A platinum-plated titanium mesh anode combines titanium’s corrosion resistance with platinum’s catalytic properties, creating an electrode for harsh electrochemical environments. The platinum coating (typically 0.1–10µm thick) enhances conductivity and extends service life.

Princeton Powder is a leading supplier of Platinum-Plated Titanium Mesh Anodes in the United States, offering Platinum/Titanium Pt/Ti Expanded Mesh Anode with extend service life. Buy customized Platinum Titanium Mesh Anode for research and industrial purposes at a competitive price.

Material | Niobium Wire, Nb |

CAS Number | 7440-03-1 |

Standard | ASTM B392 |

Color/Appearance | Gray, Metallic |

| Density | 8.57 g/cm3 |

Melting Point | 2468 ℃ |

Diameter | Customized |

Surface Treatment | Pickling or Polishing |

Description of Platinum plated titanium mesh anode

Electrolyzed water hydrogen production (PEM electrolysis) is a mature and scalable technology for industrial H2 generation. The electrolyzer cell, the core component of water electrolysis systems, produces hydrogen at the cathode and oxygen at the anode when current flows between the electrodes.

The platinum-plated titanium mesh anode is critical to electrolyzed water hydrogen production cells. Its electrocatalytic performance directly impacts: Electrolysis efficiency, Cell voltage, Energy consumption, and Overall hydrogen production cost. Selecting high-performance electrode materials (e.g., Pt/Ti anodes) is essential to optimize electrolysis efficiency and reduce operational costs in water electrolysis processes.

Specifications of Platinum Titanium Mesh Electrode

Substrate | Gr1,Gr2 pure Titanium |

Shape | Plate, mesh, tube, wire, bar etc. |

Dimension | Different dimensions and shapes are available to us |

Coatings | Platinum |

Coating Area | Double Side and connection stem |

Working Parameter | Current density≤2000A/M2 Temperature<60°C Max content of Fluoride ion is 200PPM |

Applicable electrolyte | The electrolyte contents more Cl-,or the main reaction is chlorine evolution during the electrolytic process |

Features | 1 High electrocatalytic activity 2 High current efficiency and save energy 3 High anti-erosion 4 Dimensionally stable 5 The substrate is reusable. 6 Economical and need no maintenance 7 High purity of cathode material production |

Applications | NaOH & Chlorine production Sodium Hypochlorite Generator Chlorine Dioxide Generator Chlorine industry |

Packing | Foam paper or paper as inside, carton or plywood case as outside |

Platinum-Plated Titanium Mesh Anode Application

Platinum-Coated Titanium Mesh Anode for Chlor-Alkali Industry

Chlorine Production: Replaces graphite anodes in brine electrolysis.

Sodium Hypochlorite Generators.

Platinum-Coated Titanium Mesh Anode for Water Treatment

Electrolytic Ozone Generation.

Wastewater Electrooxidation (destroys organic pollutants).

Platinum-Coated Titanium Mesh Anode for Energy

PEM Electrolyzers (Hydrogen production).

Fuel Cell Bipolar Plates.

Platinum-Coated Titanium Mesh Anode for Marine & Aerospace

Cathodic Protection for ships/offshore structures.

Lightweight Anodes for spacecraft systems.

Platinum plated titanium mesh anode Features

- High current efficiency and good electrocatalytic activity

- Proprietary Electroplating Technique Optimizes Ionization;

- Withstand high current density.