Niobium-10% Hafnium-1% C103 Powder

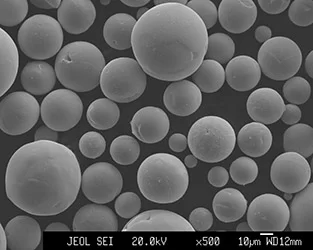

Nb-Hf Alloy Spherical Powder, also known as C103 Spherical Powder, it has a composition of Niobium-10% Hafnium-1% Titanium. AMS 7852 C103 Powder, with a particle size of 15-45 um and 45-106 um, is usually used for 3D printing process. Te high sphericity and satellite-Free c103 Niobium particles can be customized per customer’s request.

Princeton Powder is a leading supplier of c103 Niobium powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. Niobium Hafnium alloy spherical powder is for sale at a competitive price. Tantalum powders including Tantalum Nanoparticles, Tantalum Tungsten gas atomized powder, and Tantalum Disilicide powder are for sale in bulk.

C103 Niobium Hafnium Alloy Spherical Powder

Formula | Nb C103 alloy |

Synonyms | Niobium C103 spherical particles, Niobium C103 spherical powder, Niobium C103 Powder, Niobium C103 thermal spray powder, Niobium C103 gas atomized powder |

Appearance | Black Powder, Spherical Shape |

Particle Size | 0-45 um, 45-105 um, can be customized upon request |

Melting Point | 2350 °C |

Density | 8.85 g/cm 3 |

Tap Density | >5.5 g/cm³ |

Apparent density | 4.8 g/cm3 |

Description of C103 Niobium Hafnium Spherical Powder

Niobium C103 is a high-performance niobium-based alloy with approximately 10% hafnium and 1% titanium, known for its high melting point (~2,340°C) and excellent high-temperature strength. It is widely used in aerospace, particularly for rocket nozzles and turbine components. The alloy is processed through powder metallurgy and is also weldable and machinable.

Niobium C103 spherical powder, also known as Nb-Hf10Ti1 or simply C103 alloy powder, is a niobium-based alloy powder with 10% hafnium and 1% titanium. It is highly valued for its ability to maintain strength at extreme temperatures, making it essential in aerospace applications like rocket nozzles and turbine components. This alloy is increasingly used in 3D printing, where its properties allow for the creation of complex, high-performance parts that withstand harsh conditions. Its adaptability in additive manufacturing makes C103 a key material in advanced engineering.

Chemical Composition

Chemical Composition – by ICP-AES | ||||||||

| Element | Nb | Mo | Fe | Ni | Ta | Si | Cr | Ti |

Value (%) | ≥99.98 | <0.003 | <0.005 | <0.001 | <0.005 | <0.002 | <0.002 | <0.002 |

| Gas Impurities | ||||||||

| Element | C | P | O | N | ||||

Value (%) | </= 0.01 | </= 0.002 | </= 0.06 | </= 0.003 | ||||

Niobium Alloy Powder Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

Niobium C103 powder is primarily used in high-temperature aerospace applications, such as rocket nozzles, thrusters, and turbine blades, where it provides excellent strength and stability under extreme conditions. It is also utilized in the production of components for gas turbines, nuclear reactors, and advanced propulsion systems due to its resistance to heat and corrosion. Additionally, the powder is increasingly employed in additive manufacturing (3D printing) to create complex, high-performance parts for both aerospace and defense industries.

Spherical Niobium C103 spherical powder Reference

The role of additively manufactured niobium alloy C103 substrate’s surface finish and corner geometry on the silicide diffusion coating’s performance

- Nb-based C103 is an increasingly relevant material for aerospace applications due to recent advances in additive manufacturing (AM). AM enabled complex component geometries, along with the associated surface roughness, are a challenge to the survival of environmental barrier coatings (EBCs), like R512E. EBCs are necessary to provide protection for the oxidation susceptible C103 substrates in elevated temperature, oxidizing environments.

Nb-alloys like C-103 (89 wt% Nb, 10 wt% Hf, 1 wt% Ti) or Nb-1Zr (~99 wt% Nb, 1 wt% Zr) are generally easier to fabricate and more workable than Mo-alloys although they have relatively lower strength than the latter.

Powder Metallurgy: C103 can be processed using powder metallurgy techniques, where it is pressed and sintered to create high-strength components.

Welding and Machining: The alloy is weldable and machinable, allowing for its use in complex assemblies and components.

Powder Preparation: The C103 powder is first prepared and characterized for its particle size, distribution, and purity to ensure it meets specific application requirements.

Powder Metallurgy: The powder is then compacted into a desired shape using a die or mold, followed by sintering at high temperatures. This process bonds the particles together, creating a dense and strong component.

3D Printing (Additive Manufacturing): For complex geometries, the C103 powder can be used in 3D printing technologies such as Selective Laser Melting (SLM) or Electron Beam Melting (EBM). The powder is layer-by-layer melted and solidified to form precise, intricate parts.

Post-Processing: After forming, the components may undergo additional processes like machining, welding, or surface treatment to achieve the final specifications and improve properties such as oxidation resistance.

Quality Inspection: The finished components are subjected to rigorous testing and inspection to ensure they meet the required standards for mechanical properties, dimensional accuracy, and surface finish, especially for critical aerospace or defense applications.