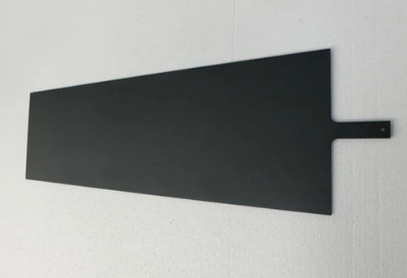

MMO (IrO2/RuO2) Coated Titanium Electrode

MMO Titanium Anodes (Mixed Metal Oxide) are advanced, corrosion-resistant electrodes designed for high-performance applications in electroplating, cathodic protection, and water treatment systems.

MMO Coated Titanium Electrodes included MMO Titanium Mesh Anodes, MMO Titanium Wire Anodes, and MMO Titanium Rod Anodes. The commonly used MMO are Ru-Ir oxide and Ir-Ta oxide. Featuring a durable titanium substrate with a mixed metal oxide coating, these anodes deliver excellent conductivity, long service life, and low maintenance operation. Ideal for industrial electrochemical processes, MMO anodes offer a cost-effective and eco-friendly alternative to traditional lead-based electrodes.

Base Material | Titanium, Grade 1 or 2 |

Coating Material | RuO2/IrO2 |

Coating thickness | 1-20 um, customize |

Material Shape | Wire, Rod, Mesh, Anode basket, customize |

| Current density | 50mA/cm2 |

Life Span | 2-5 Years |

Description of MMO (IrO2/RuO2) Coated Titanium Electrode

Electrochemical processes are widely recognized as a highly effective method for the decolorization and decontamination of wastewater, particularly from the textile and dye industries. A critical component of these systems is the electrode material, as the efficiency and outcome of pollutant degradation heavily depend on the choice of anode.

Selecting the right electrode enhances process performance by influencing the reaction mechanism and degradation products. Among advanced materials, Mixed Metal Oxide (MMO) coated titanium electrodes stand out for their high electrochemical stability, excellent oxidation capabilities, and long service life. These titanium-based electrodes feature a conductive MMO layer that provides a high surface area, strong mechanical integrity, and superior electro-catalytic activity, making them ideal for electrochemical wastewater treatment applications.

MMO (IrO2/RuO2) plated Titanium Electrode Application

MMO (IrO₂/RuO₂) Coated Titanium Electrodes are highly durable anodes used in electrochemical applications such as chlor-alkali production, seawater electrolysis, and cathodic protection. Their excellent corrosion resistance, electrocatalytic activity, and stability in harsh environments make them ideal for wastewater treatment, metal recovery, and electrolytic disinfection. These electrodes ensure long service life, low energy consumption, and high process efficiency in both industrial and environmental systems.

FAQ: MMO (IrO₂/RuO₂) Coated Titanium Electrode

What shapes and sizes are available?

Mesh: 10×10 to 100×100 (for chlorine generators)

Wire: Ø0.5-3.0mm (flexible cathodic protection)

Rods/Tubes: Ø3-50mm (high-current electrolysis)

Custom: Discs, cylinders, or stamped patterns

Which coating ratio is best for my application?

RuO₂-rich (e.g., 70% RuO₂): Optimal for chlorine production (seawater, HCl)

IrO₂-rich (e.g., 70% IrO₂): Better for oxygen evolution (PEM electrolyzers)

Balanced (50/50): General-purpose water treatment

What is an MMO (IrO₂/RuO₂) Coated Titanium Electrode?

An MMO (Mixed Metal Oxide) coated titanium electrode consists of a titanium substrate (ASTM B265) coated with a catalytic layer of iridium oxide (IrO₂) and ruthenium oxide (RuO₂)