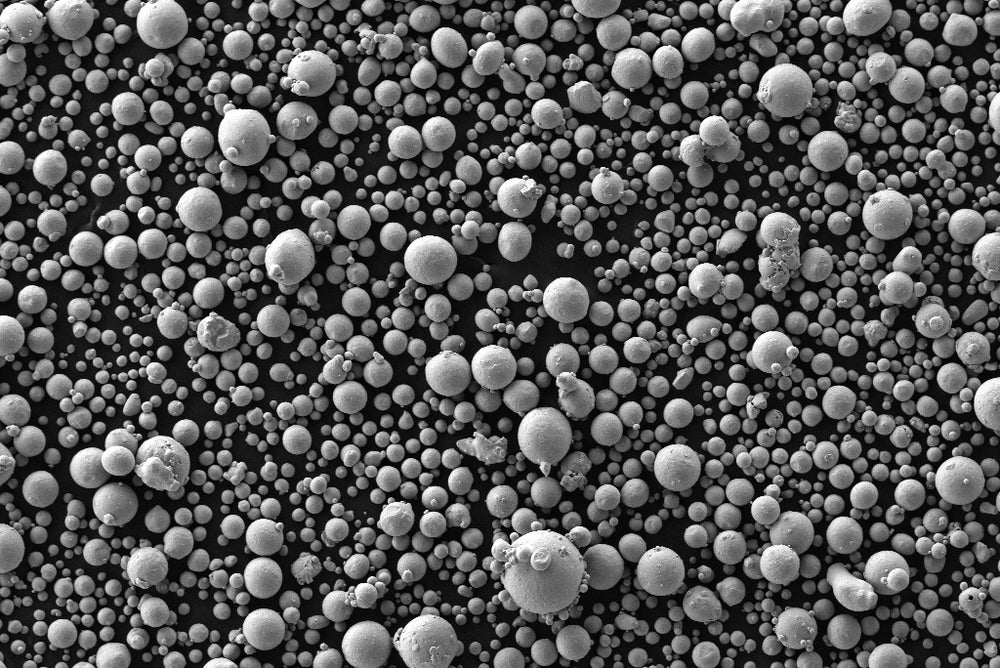

Spherical Inconel 738 Powder

Formula | Inconel 738, Inconel UNS N07738 |

Synonyms | spherical Inconel 738 particles, spherical Inconel 738 powders, Inconel UNS N07738 Powder, Inconel 738 thermal spray powder, Inconel 738 gas atomized powder |

Appearance | Black Powder |

Particle Size | 15-53 um, 45-105 um, can be customized upon request |

Melting Point | 1310-1335 °C |

Density | 8.24 g/cm 3 |

Apparent Density | 5.04 g/cm3 |

Tap Density | 4.75 g/cm3 |

Description of Spherical Inconel 738 Powder

Inconel 738 is composed primarily of nickel (Ni), with significant amounts of chromium (Cr), cobalt (Co), and molybdenum (Mo), as well as smaller quantities of aluminum (Al), titanium (Ti), and other elements.

Spherical Inconel 738 powder is a high-performance, nickel-based superalloy commonly used in applications that require excellent mechanical strength, oxidation resistance, and high-temperature stability. The alloy, designated under the Unified Numbering System (UNS) as N07738, is specifically engineered for use in environments that demand long-term service at elevated temperatures, such as in gas turbine engines and other aerospace components.

Princeton Powder is a leading supplier of Inconel 738 spherical powder. We specialize in a comprehensive range of Nickel alloy spherical powder products including inconel 718 powder, inconel 625 powder and possess extensive expertise in additive manufacturing (3D printing) industry. Inconel 738 spherical powder is for sale at a competitive price.

Chemical Composition

Chemical Composition (wt%) | ||||||||||

Item | Fe | C | Mn | Si | Ni | Cr | Mo | V | W | Al |

IN738 | ≤0.1 | 0.09-0.13 | ≤0.35 | ≤0.35 | Bal. | 15.5-16.5 | 1.5-3.0 | – | 2.4-3.0 | 3.2-3.7 |

Mg | Cu | Ti | Nb | Ta | P | S | Co |

|

| |

≤0.01 | – | 3.0-3.5 | 0.5-1.1 | 1.5-2.0 | ≤0.015 | ≤0.015 | 8.0-10.0 |

|

| |

Oxygen≤400 ppm; Nitrogen≤300 ppm

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

- Aerospace: Used in turbine blades, vanes, and other components exposed to extreme temperatures and stress.

- Power Generation: Components in gas turbines, both land-based and for aircraft.

- Additive Manufacturing: Ideal for 3D printing of complex components that require high strength and thermal resistance.

Spherical inconel 738 Powder Reference

- This study reports the successful crack-free fabrication of the non-weldable high γʹ Ni-superalloy IN 738 by laser powder bed fusion. The as-fabricated texture was composed of columnar grains with preferred orientation along <100> direction. Scanning electron microscopy and X-ray diffraction analysis revealed the presence of M(Ti, Ta, W, Mo, Nb)C and M(Cr, Mo, W)23C6 carbides along the grain boundaries.

Inconel 718 powder is typically produced through gas atomization, where molten Inconel 718 is atomized into fine droplets using high-pressure gas, resulting in spherical powder particles. Other methods include plasma atomization and the Plasma Rotating Electrode Process (PREP), both of which also produce high-purity, spherical powders ideal for additive manufacturing. These processes ensure the powder has excellent flowability, making it suitable for 3D printing and high-performance applications.

Inconel 738 powder is primarily produced through gas atomization, where molten Inconel 738 is broken into fine droplets using high-pressure gas, which then solidify into spherical particles. Plasma atomization is another method, offering high-purity, uniformly spherical powders suitable for additive manufacturing. These methods ensure the powder’s consistency and performance for high-temperature applications, such as in aerospace and turbine components.