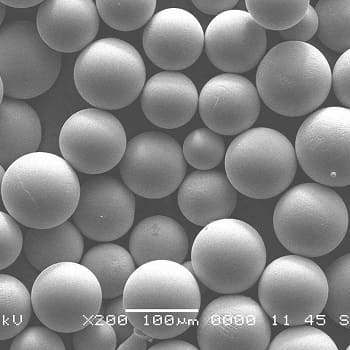

Inconel 718 Spherical Powder NiCr19NbMo powder

Formula | Inconel 718 |

Synonyms | Inconel 718 spherical particles,IN718 spherical powders, Nickel Based Metal Powder, Inconel 718 thermal spray powder, Inconel 718 gas atomized powder |

Appearance | Black Powder |

Particle Size | 0-45 um, 45-105 um, can be customized upon request |

Melting Point | 1370-1430 °C |

Density | 8.19 g/cm 3 |

Tap Density | 4.93 g/cm³ |

Apparent density | 4.2g/m3 |

Description of Inconel 718 Spherical Powder (for additive manufacturing or 3D printing)

Nickel-based Inconel 718 spherical particles is primarily composed of nickel (approximately 50-55%), with significant additions of chromium, niobium, molybdenum, and smaller amounts of titanium and aluminum. These elements contribute to its high strength, corrosion resistance, and excellent mechanical properties at elevated temperatures.

Inconel 718 fine spherical powder combines advanced alloy properties with tailored powder characteristics, making it a preferred choice for high-performance applications requiring strength, corrosion resistance, and precision in additive manufacturing (3D Printing).

Princeton Powder is a leading supplier of 3D printing Inconel 718 metal powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. With our expertise, we are confident in supporting your projects effectively and provide you with reliable solutions.

Chemical Composition

Chemical Composition (wt%) of Inconel 718 | ||||||||||

Item | Fe | C | Mn | Si | Ni | Cr | Mo | V | W | Al |

In718 | Bal. | ≤0.08 | ≤0.35 | ≤0.35 | 50.0~55.0 | 17.0~21.0 | 2.8~3.3 | – | – | 0.2~0.8 |

Mg | Cu | Ti | Nb | Zr | P | S | Co |

|

| |

≤0.01 | ≤0.3 | 0.65~1.15 | 4.75~5.5 | – | ≤0.015 | ≤0.015 | ≤1.0 |

|

| |

Oxygen≤400 ppm; Nitrogen≤300 ppm

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

- Aerospace: manufacturing critical components like turbine blades, discs, and structural parts in jet engines and rocket propulsion systems.

- Gas Turbines: Employed in components subjected to high temperatures and mechanical stresses, such as combustion chambers and turbine sections.

- Additive Manufacturing: Utilized as feedstock material in advanced 3D printing technologies to produce complex geometries with optimized mechanical properties and reduced material waste.

Spherical Inconel 718 Powder Reference

Selective laser melting of Cu-inconel 718 powder mixtures

- The selective laser melting of mechanically mixed Inconel 718 and copper powders is studied by processing feedstocks of different Cu content at various energy inputs. It was observed that with the increase of the Cu content the width of the molten pools decreases while the porosity of the samples increases.

FAQ Tantalum Carbide Powder

What is Inconel 718 ASTM B637 IN718 powder?

Inconel 718 powder is a nickel-chromium-based superalloy powder containing significant amounts of iron, niobium, and molybdenum. It is precipitation-hardenable and maintains excellent mechanical properties from cryogenic temperatures up to 700°C (1300°F). The powder form is primarily used in additive manufacturing (3D printing), powder metallurgy, and thermal spray applications.

What manufacturing processes use Inconel 718 powder?

Additive Manufacturing: SLM (Selective Laser Melting), EBM (Electron Beam Melting), DED (Directed Energy Deposition)

Powder Metallurgy: Hot Isostatic Pressing (HIP), Metal Injection Molding (MIM)

Thermal Spray Coatings: HVOF, Plasma Spray

Traditional Manufacturing: As feedstock for laser cladding

What particle size ranges are available?

Inconel 718 Fine (15-45μm) powder: Optimal for LPBF/SLM processes

Inconel 718 Medium (45-106μm) Powder: Suitable for EBM and DED

Inconel 718 Coarse (106-150μm) Powder: Used for thermal spray applications

Custom sizes: Available upon request