Inconel 625 Spherical Microns Powder

Inconel 625 powder, also know as ASTM B443, AMS 5666, and UNS N06625 powder. The standard composition of Inconel 625 follows a Ni-Cr-Mo-Nb formulation with ≥58% nickel matrix, 20-23% chromium for corrosion resistance, 8-10% molybdenum for high-temperature strength, and 3.15-4.15% niobium for solution strengthening and creep resistance

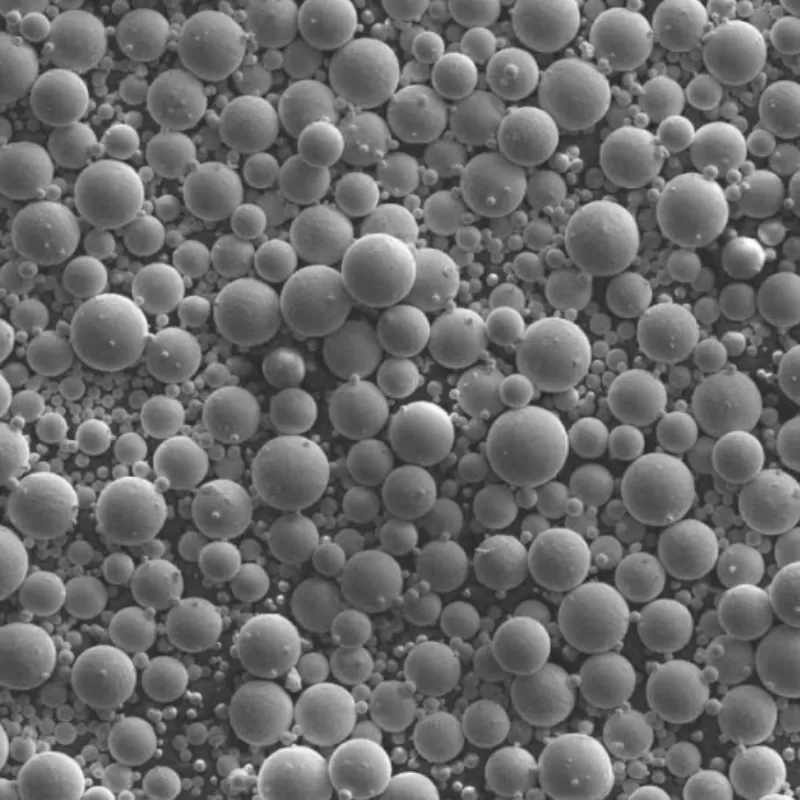

Spherical alloy 625 powder has excellent sphericility, micron particle size, and low oxygen content. 15-53 um Gas-Atomized Inconel 625 AM Powder is the most common grade.

Princeton Powder is a leading supplier of Inconel 625 super alloy powder. Nickel alloy powders including Nitinol Niti Round Powder, Inconel 718 Spherical Powder, and Spherical Hastelloy X Powder are for sale in bulk.

Inconel 625 Spherical Powder

Formula | Inconel 625 |

Synonyms | Inconel 625 spherical particles,IN625 spherical powders, Nickel Based Metal Powder, Inconel 625 thermal spray powder, Inconel 625 gas atomized powder |

Appearance | Black Powder |

Particle Size | 0-45 um, 45-105 um, can be customized upon request |

Melting Point | 1288–1349°C |

Density | 8.44 g/cm 3 |

Tap Density | >5.0 g/cm³ |

Apparent density | 4.32g/m3 |

Description of Spherical Nickel Alloy 625 Powder

Gas atomized Inconel 625 spherical powder it is a nickel-based superalloy powder widely used in additive manufacturing (AM), thermal spray, powder metallurgy (PM), and metal injection molding (MIM).

UNS N06625 Nickel Plasma Atomized Powder is mainly applied in laser powder bed fusion (LPBF) or selective laser melting (SLM) process. It is ultra-high purity and fine powders with a small particle size of 15–45 μm.

Water Atomized ASTM B443 Nickel powder has a irregular shape, powder metallurgy (PM) and metal injection molding (MIM).

Aerospace Grade IN625 Powder Chemical Composition

Chemical Composition:

Chemical Composition (wt%) of Inconel 625 | ||||||||||

Item | Fe | C | Mn | Si | Ni | Cr | Mo | V | W | Al |

In625 | ≤5.0 | ≤0.1 | ≤0.5 | ≤0.5 | Bal. | 20.0~23.0 | 8.0~10.0 | – | – | ≤0.4 |

Mg | Cu | Ti | Nb | Zr | P | S | Co |

|

| |

– | ≤0.07 | ≤0.4 | 3.15~4.15 | – | ≤0.015 | ≤0.015 | ≤1.0 |

|

| |

Oxygen≤400 ppm; Nitrogen≤300 ppm

Alloy 625 powder Particle Size distribution

Inconel 625 AM Powder is available in particles of 15-45μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Alloy Nickel 625 Fine Powder (15–45 μm) → Used in SLM (Selective Laser Melting), LPBF (Laser Powder Bed Fusion)

Alloy Nickel 625 Medium Powder (45–106 μm) → Used in EBM (Electron Beam Melting), DED (Directed Energy Deposition)

Alloy Nickel 625 Coarse Powder (106–150 μm+) → Used in thermal spray (HVOF, Plasma Spray)

Nickel Alloy IN625 Plasma Spray powder Applications

Spherical Inconel 625 powder due to its exceptional properties, finds extensive application across various industries, primarily where high strength, excellent corrosion resistance, and heat resistance are crucial.

Aerospace Industry: Gas Turbine Components and Aircraft Exhaust Systems

Nuclear Reactor Components

Marine Industry: Offshore and Subsea Equipment

Additive Manufacturing

Spherical Inconel 625 Powder Reference

Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting

- Selective laser melting (SLM), an additive manufacturing process, is capable of manufacturing metallic parts with complex shapes directly from computer-aided design (CAD) models. SLM parts are created on a layer-by-layer manner, making it more flexible than traditional material processing techniques.

FAQ UNS N06625 Nickel alloy Powder

What is Inconel 625 powder?

Inconel 625 powder is a nickel-based superalloy in powdered form, composed primarily of nickel (Ni), chromium (Cr), molybdenum (Mo), and niobium (Nb). It is known for its high strength, corrosion resistance, and excellent performance in extreme temperatures, making it ideal for aerospace, oil & gas, chemical processing, and additive manufacturing (3D printing).

How does Inconel 625 compare to Inconel 718?

| Property | Inconel 625 | Inconel 718 |

|---|---|---|

| Main Alloys | Ni-Cr-Mo-Nb (no Ti/Al) | Ni-Cr-Fe-Nb-Ti-Al (age-hardenable) |

| Strength | High (solution-strengthened) | Higher (precipitation-hardened) |

| Max Temp. | 982°C (1800°F) | 704°C (1300°F) |

| Corrosion Res. | Superior | Good |

| Cost | Moderate | Higher |

What post-processing is required for 3D-printed Inconel 625 parts?

Stress relief annealing (to reduce residual stresses).

Hot Isostatic Pressing (HIP) (improves density & mechanical properties).

Machining/Finishing (for tight-tolerance components).