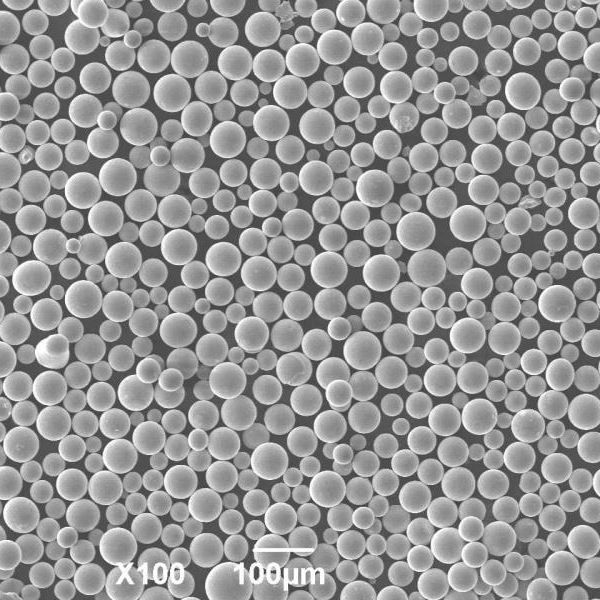

High Entropy Alloy Spherical Powder

Our FeCoNi High Entropy Alloy (HEA) Powder is a high-performance, multi-component alloy powder composed primarily of iron (Fe), cobalt (Co), and nickel (Ni). Designed for advanced manufacturing applications such as additive manufacturing (3D printing), metal injection molding (MIM), and thermal spraying, this powder offers excellent mechanical properties, corrosion resistance, and thermal stability.

FeCoNi is a foundational ternary HEA system that forms a stable face-centered cubic (FCC) structure with superior strength and ductility across a wide temperature range. Available in nano or micron sizes with high purity, FeCoNi HEA powder enhances wear-resistant coatings and structural applications. Princeton Powder is a leading supplier offering customized compositions for industrial and research needs.

FeCoNiCr High Entropy Alloy Spherical Powder

Formula | FeCoNiCr, FeCoNiCrTi, FeCoNiCrAl, FeCoNiCrMn, FeCoNiCrMo |

Synonyms | FeCoNiCr spherical particles, FeCoNiCr spherical powders, FeCoNiCr Powder, FeCoNiCr thermal spray powder, FeCoNiCr gas atomized powder |

Appearance | Black Powder |

Particle Size | 0-45 um, 15-53 um, 45-105 um, can be customized upon request |

Melting Point | 1300 – 1400°C |

Density | 7.5 -8.2 g/cm 3 |

Thermal Conductivity | 10-30 W/mK |

Tensile Strength | 600-1100 MPa |

Description of FeCoNiCr high-entropy alloys (HEAs) Spherical Powder

FeCoNiCr high-entropy alloys (HEAs) are advanced materials composed of nearly equal atomic percentages of iron, cobalt, nickel, and chromium, known for their high strength, excellent corrosion resistance, good thermal stability, wear resistance, and magnetic properties, making them ideal for structural components, wear-resistant coatings, magnetic materials, and corrosion-resistant parts in industries such as aerospace, automotive, electronics, and chemical processing.

The FeCoNiCr high-entropy alloy powder series features powders with a balanced mix of iron, cobalt, nickel, and chromium, renowned for their exceptional strength, corrosion resistance, and thermal stability. Main products include high-performance aerospace components, wear-resistant coatings, and durable industrial parts. These powders are used in additive manufacturing and powder metallurgy to produce advanced parts with superior mechanical properties and long-term reliability.

Princeton Powder is a leading supplier of FeCoNiCr HEA powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. Below HEA powders are for sale at a competitive price.

- FeCoNiCrMo HEA Powder

- FeCoNiCrMn HEA Powder

- FeCoNiCrAl HEA Powder

- FeCoNiCrTi HEA Powder

- FeCoNiCr HEA Powder

FeCoNiCr HEA powder Chemical Composition

| Element | Composition |

|---|---|

| Iron (Fe) | Balance |

| Cobalt (Co) | 35-50% |

| Nickel (Ni) | 10-30% |

| Chromium (Cr) | 8-12% |

| Carbon (C) | <0.5% |

| Silicon (Si) | <1.5% |

| Manganese (Mn) | <1% |

FeCoNiCr HEA powder Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

FeCoNiCr HEA powder Applications

Additive Manufacturing (AM) / 3D Printing

Powder Metallurgy

Cold Spray & Thermal Spray Coatings

Metal Injection Molding (MIM)

Material Research & Development

Spherical FeCoNiCr high-entropy alloys (HEAs) Powder Reference

Air-oxidation of FeCoNiCr-based quinary high-entropy alloys at 700–900 °C

The oxidation of three quinary equimolar high-entropy alloys, containing FeCoNiCrAl, FeCoNiCrMn, and FeCoNiCrSi was studied in dry air at 700–900 °C. The Mn-containing alloy was single-phase, while both Al- and Si-containing alloys were dual-phase. The oxidation kinetics of all the alloys followed the parabolic rate law, regardless of temperature and alloy composition. The oxidation rates of both Al- and Si-containing alloys were lower than those of the quaternary FeCoNiCr alloy, while those of the Mn-containing alloy went to an opposite direction.

High entropy alloys are typically composed of elements with different crystal structures and exhibit several unique properties compared to conventional alloys. HEAs often possess high strength, hardness, wear resistance, thermal stability, and corrosion resistance.

The high-entropy alloys (HEAs) are essentially solid-solution alloys that contain multiprincipal elements in simple crystal structure such as body-centered cubic (BCC), face-centered cubic (FCC), and hexagonal close-packed (HCP) lattices.

This renders the high entropy alloying concept, where none of the elements prevails, into a class of Fe-based materials which we refer to as high entropy steels. Overview of the mechanical properties of High and Medium Entropy Alloys and Medium and High Entropy Steels.