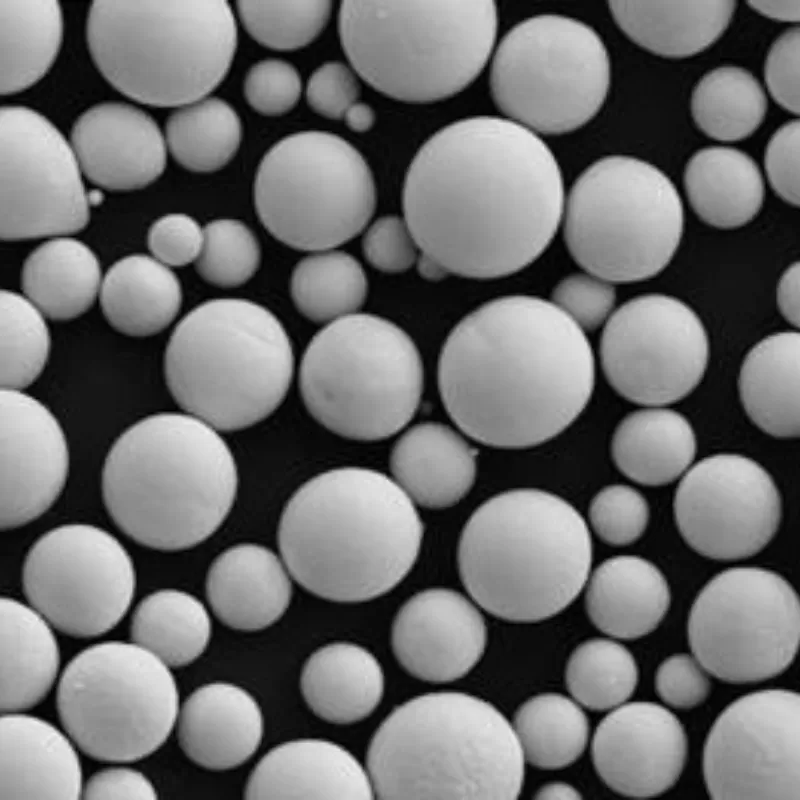

Nickel Based Spherical Hastelloy X Powder

Formula | Hastelloy X, UNS NO6002, GH3536, NC22FeD |

Synonyms | spherical Hastelloy X particles, spherical Hastelloy X powders, Hastelloy X Powder, Hastelloy X thermal spray powder, Hastelloy X gas atomized powder |

Appearance | Black Powder, spherical shape |

Particle Size | 15-53 um, 45-105 um, can be customized upon request |

Melting Point | 1177 °C |

Density | 8.22 g/cm 3 |

Tensile Strength, Ultimate | 755 MPa |

Tensile Strength, Yield | 385 MPa |

Description of Spherical Hastelloy X Powder

Spherical Hastelloy X powder is a nickel-based superalloy known for its excellent strength and oxidation resistance at high temperatures, up to 1200°C (2190°F). It is composed primarily of nickel, with significant amounts of chromium, molybdenum, and iron, making it ideal for demanding environments like aerospace and gas turbines. The powder is typically produced via gas or plasma atomization, resulting in highly spherical particles that offer superior flowability for additive manufacturing. Its high purity and consistent particle size distribution make it particularly suitable for 3D printing complex, high-strength components.

Princeton Powder is a leading supplier of spherical Hastelloy X powder. With our expertise, we are confident in supporting your projects effectively and provide you with reliable solutions. Hastelloy X powder is for sale at a competitive price.

Chemical Composition

Chemical Composition (wt%) | ||||||||||

Item | Fe | C | Mn | Si | Ni | Cr | Mo | V | W | Al |

| Hastelloy X | 17.0-20.0 | ≤0.15 | ≤1.0 | ≤1.0-2.5 | Bal. | 20.5-23.0 | 8.0-10.0 | – | 0.2-1.0 | – |

Mg | Cu | Ti | Nb | Zr | P | S | Co |

|

| |

– | – | – | – | – | ≤0.015 | ≤0.015 | 0.5-2.5 |

|

| |

Oxygen≤400 ppm; Nitrogen≤300 ppm

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

- Aerospace: Ideal for components in jet engines, gas turbines, and other high-temperature parts.

- Industrial Gas Turbines: Used in turbine blades, combustors, and other parts subjected to extreme conditions.

- Additive Manufacturing: Particularly suited for 3D printing complex, high-strength parts for aerospace and industrial applications.

Spherical Hastelloy X Powder Reference

- Defects in materials manufactured via laser powder bed fusion challenge this manufacturing process’ dependability and may prevent it from being comprehensively used for structural components, particularly those intended to operate under dynamic loading conditions. This study aims to investigate the effect of spatter-driven lack of fusion on the mechanical properties of Hastelloy X, with a particular focus on fatigue performance. Mechanical test specimens were manufactured in two builds with different build rates and monitored through in-situ optical tomography.

When it comes to high-temperature performance, both alloys exhibit remarkable stability. However, Hastelloy X boasts a slightly higher temperature tolerance, withstanding temperatures up to 1205°C, while Inconel 625 maintains its strength and corrosion resistance up to 980°C.

HASTELLOY X is a wrought nickel base alloy with excellent high temperature strength and oxidation resistance.