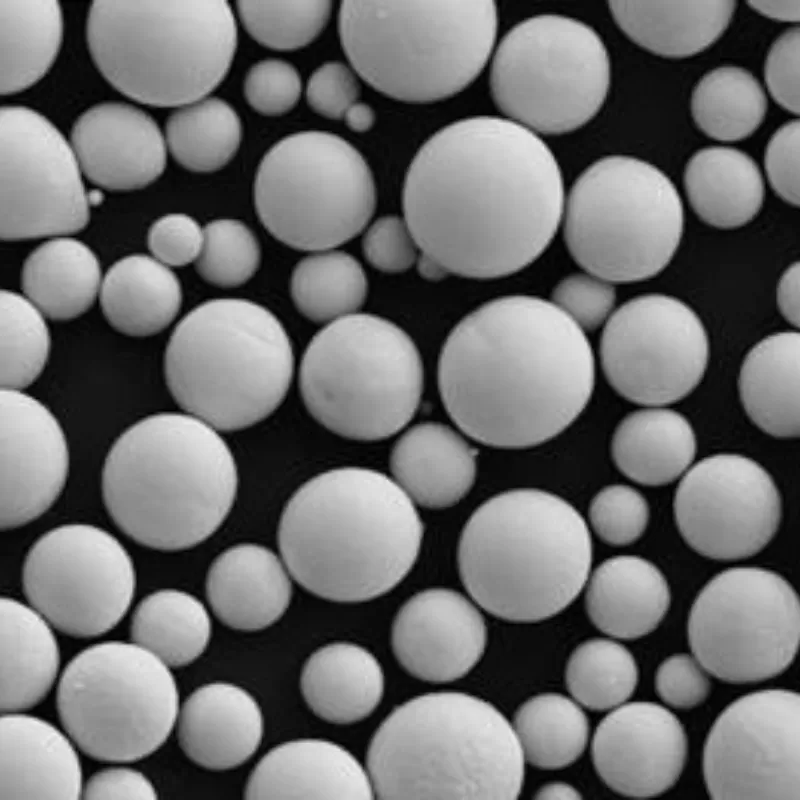

Spherical Hastelloy C-276 Powder

Formula | Alloy C-276, Hastelloy C276 |

Synonyms | spherical Alloy C-276 particles, spherical Hastelloy C276 powders, Hastelloy C-276 Powder, Alloy C276 thermal spray powder, Hastelloy C276 gas atomized powder |

Appearance | Black Powder, spherical shape |

Particle Size | 15-53 um, 45-105 um, can be customized upon request |

Melting Point | 1427°C |

Density | 8.89 g/cm 3 |

Tensile Strength, Ultimate | 790 MPa |

Tensile Strength, Yield | 355 MPa |

Description of Spherical Hastelloy C-276 Powder

Spherical Hastelloy C-276 powder is a nickel-based superalloy known for its exceptional corrosion resistance, particularly against strong acids and chlorides. The alloy is composed of nickel, molybdenum, chromium, and tungsten, making it ideal for use in chemical processing and marine environments. Produced through gas or plasma atomization, the powder’s spherical shape ensures excellent flowability for additive manufacturing. Its high purity and corrosion resistance make it suitable for 3D printing complex, high-performance components.

Princeton Powder is a leading supplier of alloy c276 powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. Spherical Hastelloy C-276 powder is for sale at a competitive price.

Chemical Composition

| Ni | Cr | Fe | Mo | W | Co | V | P | S | C | Mn | Si | |

| min | bal. | 14.5 | 4 | 15 | 3 | |||||||

| max | 16.5 | 7 | 17 | 4.5 | 2.5 | 0.35 | 0.025 | 0.01 | 0.01 | 1 | 0.08 |

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

- Chemical Processing: Used in reactors, heat exchangers, and piping systems exposed to corrosive chemicals.

- Marine Environments: Ideal for components in offshore and underwater equipment.

- Additive Manufacturing: Perfect for 3D printing complex, corrosion-resistant parts for industrial and chemical applications.

Spherical Hastelloy C-276 powder Reference

- A new structure with nickel-based Hastelloy C276 alloy cladding on creep resistant steel P91 was developed in this study for nuclear applications. The microstructure, including precipitation and grain size, boundaries, orientation and hardness distribution of cladding structures with/without post heat treatment were explored using a range of microscopy techniques and hardness testing.

Both Alloy C276 and 316 stainless steel are highly resistant to corrosion. However, alloy C276 is more resistant to corrosion in high-temperature environments, while 316 stainless steel is more resistant to corrosion in low-temperature environments.

Nickel Alloy C276 is used for welding materials of similar chemical composition as well as dissimilar materials of nickel base alloys, steels and stainless steels. This alloy can also be used for cladding steel with nickel-chrome-molybdenum weld metal.

Hastelloy C-276, which is also sold as Nickel Alloy C-276, is a nickel-molybdenum-chromium wrought alloy.