Molybdenum Rhenium Alloy Mo-Re Spherical Powder

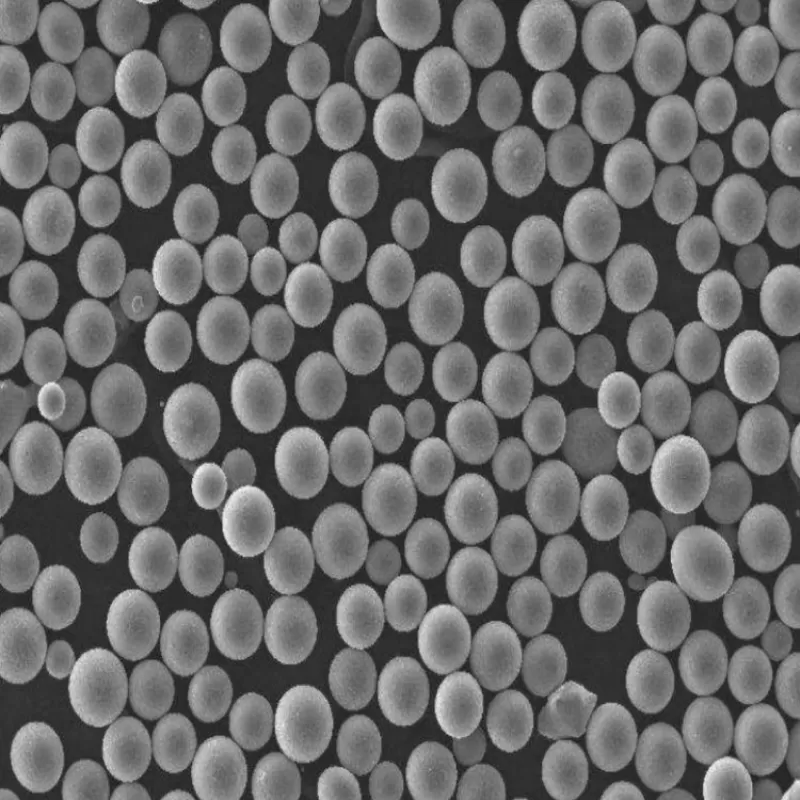

Spherical Molybdenum Rhenium Alloy powder, also known as Mo-Re Spherical Powder, is a high-performance refractory alloy powder composed of molybdenum and rhenium, offering exceptional high-temperature strength, ductility, and thermal stability. Produced through gas atomization or plasma rotating electrode processes, it features perfectly spherical morphology for excellent flowability in additive manufacturing (SLM, EBM) and powder metallurgy applications. This alloy is ideal for aerospace components, nuclear reactors, medical devices, and extreme environment applications due to its creep resistance and corrosion durability. Available in customizable particle sizes (15-53µm, 45-105µm) with low oxygen content (<0.1%) for superior sintering and mechanical properties.

Princeton Powder is a leading supplier of Molybdenum Rhenium Alloy refractory powder. Molybdenum powders including Molybdenum metal Powder, Titanium Zirconium Molybdenum (TZM) Alloy Powder, and Molybdenum Boride Powder are for sale in bulk.

Molybdenum Rhenium Alloy Mo-Re Spherical Powder

Formula | Molybdenum Rhenium, Mo-Re, Mo52.5Re47.5, Mo55.5Re44.5, Mo58.5Re41.5 |

Synonyms | Mo-Re spherical particle, Molybdenum Rhenium spherical powder, Molybdenum Rhenium Powder, Molybdenum Rhenium thermal spray powder, Molybdenum Rhenium gas atomized powder |

Appearance | Gray powder |

Particle Size | 0-45 um, 45-105 um, can be customized upon request |

Rhenium Content % | 41.5%, 44.5%, 47.5% |

Purity | 99.9% min |

Tap Density | N/A |

Apparent density | N/A |

Description of Molybdenum Rhenium Alloy Spherical Powder

Molybdenum-Rhenium (MoRe) Alloy Spherical Powder is a high-density, high-performance material with excellent mechanical strength, corrosion resistance, and a high melting point. Its spherical particles, produced via atomization, are ideal for aerospace, medical, and electronic applications that require durability in extreme environments. The alloy typically contains an equal composition of molybdenum and rhenium, offering exceptional resistance to high temperatures.

Princeton Powder is a leading supplier of Molybdenum-Rhenium alloy powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. Molybdenum-Rhenium alloy powder is for sale at a competitive price.

Chemical Composition

Impurities Content

Element | Maximum | Typical | Element | Maximum | Typical | Element | >Maximum | Typical |

Fe | 0.0050 | 0.0030 | Sb | 0.0005 | 0.0005 | Zn | 0.0005 | 0.0005 |

Ni | 0.0030 | 0.0020 | Pb | 0.0005 | 0.0005 | W | 0.0200 | 0.0150 |

Cr | 0.0010 | 0.0005 | Ca | 0.0015 | 0.0010 | K | 0.0130 | 0.0100 |

Cu | 0.0010 | 0.0005 | Cd | 0.0005 | 0.0005 | Na | 0.0010 |

|

Si | 0.0020 | 0.0010 | Co | 0.0005 | 0.0005 | C | 0.0060 | 0.0030 |

Al | 0.0015 | 0.0010 | As | 0.0005 | 0.0005 | N | 0.0150 | 0.0100 |

Mg | 0.0015 | 0.0010 | Bi | 0.0005 | 0.0005 | S | 0.0020 | 0.0010 |

Mn | 0.0005 | 0.0005 | Ti | 0.0005 | 0.0005 | P | 0.0010 | 0.0010 |

Sn | 0.0005 | 0.0005 | V | 0.0005 | 0.0005 | — | — | — |

Molybdenum Rhenium Spherical Powder Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

Molybdenum-Rhenium (MoRe) Alloy is used in applications requiring high strength, durability, and heat resistance, such as rocket nozzles, heat shields, and other aerospace components. It’s also utilized in medical implants due to its biocompatibility, as well as in electronics for filaments and thermocouples. Additionally, it’s valuable in the nuclear industry for components that must withstand high radiation and extreme temperatures.

Spherical Molybdenum Rhenium Alloy Spherical Powder Reference

Evaluating Molybdenum-rhenium Alloys through Additive Manufacturing

- This work demonstrates the use of laser powder bed fusion to produce several Mo-Re alloys by additively manufacturing mechanically mixed pure elemental powders. Relationships are explored between mechanical properties regarding build orientation, laser speed, rhenium alloy content, and the addition of 3% hydrogen to the argon shield gas.