Vanadium Oxide Nanopowder VO2 (CAS 12036-21-4)

Vanadium oxide VO2 nanopowder is a fine, nanoscale material with excellent electrical, optical, and catalytic properties, widely used in advanced energy storage, catalysis, and sensor applications. It is particularly valued for its variable oxidation states, allowing it to be tailored for specific uses in electrochromic devices and lithium-ion batteries. With a high surface area and chemical reactivity, vanadium oxide nanopowder enhances performance in applications requiring rapid ion exchange and efficient conductivity.

Princeton Powder is a leading supplier of Vanadium oxide VO2 nanoparticles. Vanadium oxide powder is for sale at a competitive price.

Formula | Vanadium oxide, VO2 |

CAS Number | 12036-21-4 |

Purity | 99.5% min |

Synonyms | Vanadium oxide powder, Vanadium oxide nanopowder, Vanadium oxide nanoparticles, VO2 Powder |

Particle Sizes | 50 nm, 80 nm, 100 nm |

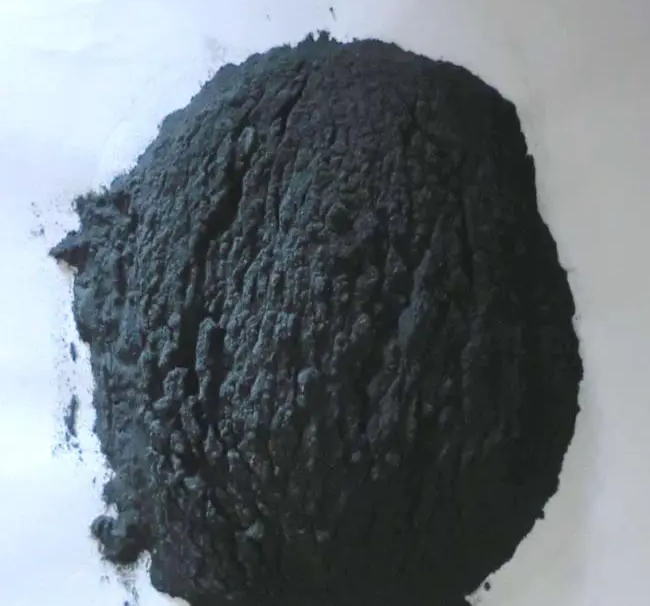

Appearance | Gray Powder |

Melting Point | 1967 °C |

Water solubility | Insoluble |

Density | 4.34 g/cm 3 |

Description of Vanadium Oxide Powder (Nano particles, Nanopowder)

Vanadium oxide nanopowder, primarily composed of vanadium (V) and oxygen (O), is a nanoscale compound with variable chemical forms like VO₂ and V₂O₅, each offering unique electrical and catalytic properties. This compound is highly versatile due to vanadium’s multiple oxidation states, making it ideal for applications in energy storage systems, catalysis, and electrochromic devices. Its high surface area and reactivity at the nanoscale enhance ion exchange and conductivity, boosting performance in lithium-ion batteries and smart windows.

Main properties of Vanadium Oxide Powder

Variable Oxidation States: Vanadium oxide can exist in multiple oxidation states (e.g., VO, VO₂, V₂O₅), allowing it to exhibit different electrical and optical properties, which are useful in tunable devices.

High Electrical Conductivity: Vanadium oxide, especially VO₂, shows a metal-to-insulator transition at a specific temperature, making it suitable for use in smart windows, sensors, and switching devices.

Catalytic Activity: Due to its ability to facilitate oxidation-reduction reactions, vanadium oxide is widely used as a catalyst in chemical processes, such as sulfuric acid production and hydrocarbon processing.

High Surface Area (for Nanopowder): Nanopowder forms of vanadium oxide provide a high surface-to-volume ratio, enhancing reactivity and efficiency in applications like energy storage and catalysis.

Thermal Stability and Oxidation Resistance: Vanadium oxide has good stability at high temperatures, making it suitable for applications in coatings, refractories, and high-temperature environments.

Chemical Composition of Vanadium Oxide Powder

| Appearance | Black Powder |

| Purity | >99.90 % |

| Particle Size | 30-60 nm |

| Al | <0.05% |

| Fe | <0.05% |

| Bi | <0.05% |

| Zn | <0.01% |

| Ti | <0.01% |

| Ca | <0.01% |

| Na | <0.01% |

| Pb | <0.0002% |

| Sn | <0.0002% |

Application of Vanadium Oxide Powder

Vanadium oxide powder is widely used in energy storage, particularly in lithium-ion batteries and vanadium redox flow batteries, due to its high conductivity and ability to facilitate rapid ion exchange. It is also employed in smart windows, sensors, and catalysts, where its variable oxidation states and electrical properties enable advanced functionality in adaptive and chemical processes.

Vanadium Oxide Powder Scholar Articles

Pure Single-Crystal Rutile Vanadium Dioxide Powders: Synthesis, Mechanism and Phase-Transformation Property

Abstract:Pure single-crystal rutile-type VO2 has been synthesized via the hydrothermal reaction of V2O5, oxalic acid, and tungstenic acid at low temperatures. The products have been characterized by means of X-ray diffraction, transmission electron microscopy, scanning electron microscopy, selected area electron diffraction, differential scanning calorimetry, and X-ray photoelectron spectroscopy. It is shown that a part of VO2 powders have a “snowflake” morphology assembled by VO2 rods which have a monoclinic structure with a preferential orientation along 110 direction. The adulterating agent tungstenic acid plays a key role in the synthesis of rutile phase. The DSC results indicated that the metal-semiconductor transition temperature of VO2 powders was reduced to room temperature or below. The reaction details and mechanisms are described and discussed. The substitution of a part of V atoms with larger W atoms induces the distortion of the VO6 octahedra, promoting the transition from VO2 (B) to VO2 (R).