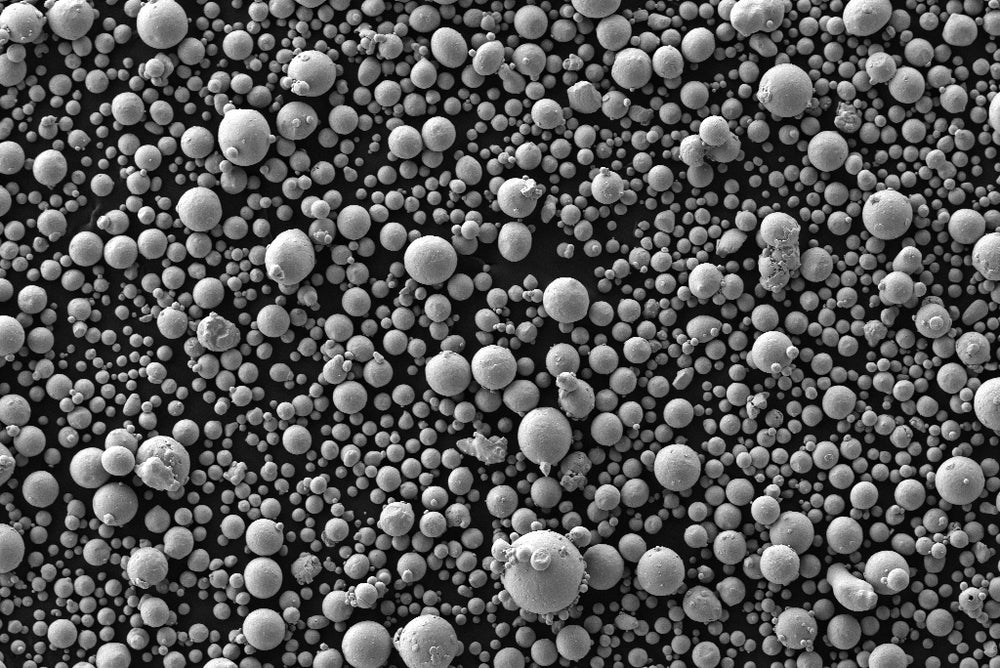

Titanium TA15 Spherical Powder

Formula | Titanium TA 15, Ti-6.5Al-2Zr-1Mo-1V |

Synonyms | Titanium TA 15 spherical particles, Titanium Grade 15 spherical powders, Grade 15 Titanium Ti Powder, Titanium Grade 15 thermal spray powder, Titanium Grade 15 gas atomized powder |

Appearance | Black Powder |

Particle Size | 0-45 um, 45-105 um, can be customized upon request |

Melting Point | 1610 °C |

Density | 4.5 g/cm 3 |

Tensile Strength: Ultimate (UTS) | 540 Mpa |

Tensile Strength: Yield | 430 Mpa |

Description of Titanium TA15 Powder

Titanium TA 15 Powder is a titanium alloy powder with 0.25% nickel and 0.05% molybdenum, offering enhanced corrosion resistance, particularly in chloride-rich environments. This makes it ideal for applications in chemical processing, marine environments, and other harsh conditions. The powder is typically used in additive manufacturing and other processes where its corrosion-resistant properties are critical.

Princeton Powder is a leading supplier of Titanium TA15 powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. TA15 Titanium powder is for sale at a competitive price.

Chemical Composition

Specifications for TA15 Titanium Alloy Powder

| Parameter | Specification | Standard |

|---|---|---|

| Aluminum content | 4.5 – 6 wt% | ASTM B348, Grade 15 |

| Tin content | 2 – 3.5 wt% | ASTM B348, Grade 15 |

| Zirconium content | 3.5 – 5.5 wt% | ASTM B348, Grade 15 |

| Molybdenum content | 4 – 6 wt% | ASTM B348, Grade 15 |

| Titanium | Balance | ASTM B348, Grade 15 |

| Particle size | 10 – 45 μm, max 150 μm | ASTM B348 |

| Apparent density | ≥ 2.7 g/cc | ASTM B212 |

| Tap density | ≥ 4 g/cc | ASTM B527 |

| Flow rate | ≥ 25 s/50 g | ASTM B213 |

| Oxygen content | ≤ 0.25 wt% | ASTM B348 |

| Nitrogen content | ≤ 0.03 wt% | ASTM B348 |

| Carbon content | ≤ 0.08 wt% | ASTM B348 |

| Iron content | ≤ 0.25 wt% | ASTM B348 |

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

- Chemical Processing: Used in the production of components for chemical processing equipment, where resistance to corrosion is critical.

- Marine Environments: Ideal for marine applications due to its superior resistance to seawater corrosion.

- Additive Manufacturing: Suitable for 3D printing and other powder metallurgy processes, where its corrosion resistance can be fully utilized.

Spherical Titanium TA15 Powder Reference

Preparation of TA15 Titanium Alloy Powder by EIGA for Laser 3D Printing

- TA15 titanium alloy powder was prepared by electrode induction melting gas atomization (EIGA) for laser 3D printing. The effect of different smelting power on printable powder production rate, particle size, powder morphology, apparent density, flowability were studied. The results showed that production rate of printable powder and sphericity were improved with the increase of smelting power, and particle size was decreased.

Titanium TA15 is a titanium alloy primarily composed of:

Titanium (Ti): Balance (~88-90%)

Aluminum (Al): 6%

Zirconium (Zr): 2%

Molybdenum (Mo): 2%

This alloy is known for its high strength, good thermal stability, and excellent weldability, making it suitable for aerospace and high-performance applications.