Tantalum Powder (Ta Spherical Powder)

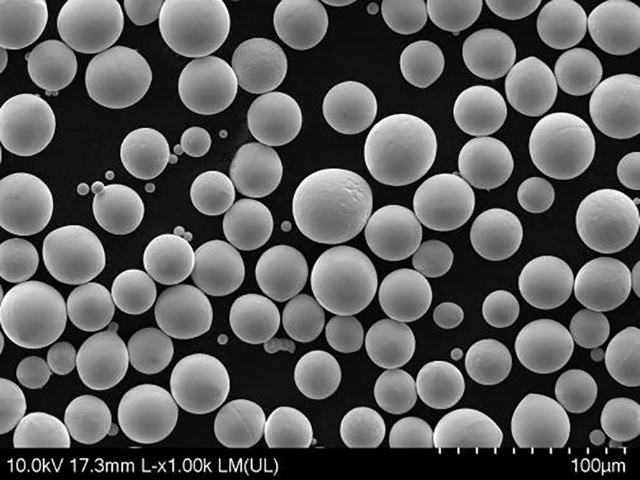

Princeton Powder is a leading supplier of high-purity tantalum metal powder, offering particle sizes ranging from tantalum nanopowder to 325 mesh and 15-53 µm tantalum micron powder. Our ASTM B708 spherical Tantalum Powder, with low oxygen content, high sphericity, and excellent flowability, is used in various applications, including powder metallurgy, thermal spray processes, and additive manufacturing (3D printing).

We provide a wide range of Tantalum powder products including Tantalum Carbide (TaC) Powder, Tantalum Nitride (TaN) Powder, Tantalum(V) oxide, and Tantalum Disilicide powder. Our Satellite-Free Spherical Tantalum Ta powder is for sale at a competitive price in the USA.

Formula | Tantalum Ta |

CAS Number | 7440-25-7 |

Purity | 99.95% min |

Synonyms | Tantalum nano powder, Tantalum spherical powders, Tantalum meta powder, Tantalum thermal spray powder, Ta microns powder |

Particle Sizes | 325 mesh or be customized |

Appearance | Black Color |

Melting Point | 2996°C |

Boiling Point: | 5425°C |

Apparent Density | >9.5 |

Tap Density | >10.5 |

Description of Spheroidized Tantalum Powder

Tantalum powder is a critical refractory metal powder, known for its high melting point, excellent chemical stability, and conductivity, making it ideal for high-temperature tools, chemical industry applications, capacitors, and wear-resistant components. Its spherical shape and uniform particle size enhance flowability and suitability for powder metallurgy and additive manufacturing, setting it apart from other metal powders.

Spherical tantalum powder plays a pivotal role in advanced manufacturing processes such as tantalum powder metallurgy and additive manufacturing. Its uniform particle shape and size improve flowability and packing density, making it perfect for producing high-performance components. Applications range from aerospace to electronics, where both tantalum carbide powder and tantalum metal powder variants are valued for their outstanding mechanical and thermal properties.

Chemical Composition of Spherical Tantalum Powder

|

Chemical Composition |

Wt % |

|

Ta |

≥ 99.95 |

|

Ti |

<0.01 |

|

Mo |

<0.005 |

|

W |

<0.01 |

|

Nb |

<0.01 |

|

Si |

<0.005 |

|

Ni |

<0.005 |

|

Fe |

<0.01 |

|

Mg |

<0.001 |

|

Cu |

<0.001 |

|

Al |

<0.001 |

|

Ca |

<0.001 |

|

Gas Impurities |

|

|

O |

≤0.03 |

|

N |

≤0.001 |

|

C |

≤0.001 |

|

H |

≤0.001 |

Particle Size distribution Spherical Tantalum Powder

0-15 μm, 15-53 μm, 45-105 μm, 45-150 μm Tantalum Spherical Powder is available (Various particle sizes can be customized)

Application of Spherical Tantalum Powder

Tantalum powder is used in a variety of advanced manufacturing processes, including Electron/Laser beam additive manufacturing (3D printing), thermal spray coating methods such as plasma spraying and high-velocity oxygen fuel (HVOF) spraying, metal injection molding (MIM), as well as casting and powder metallurgy (PM) processes, where it is integrated to fabricate tantalum-based alloys.

Spherical Tantalum Powder Reference

Spherical tantalum feed powder for metal additive manufacturing

- Tantalum is the new “T” metal for additive manufacturing (AM) applications. Test parts and coupons have also been successfully printed via Laser-Powder Bed Fusion process. The physical properties of the printed tantalum confirm suitability for a wide variety of applications including aerospace, medical and dental industries.

Spherical tantalum powder is typically produced using methods such as gas atomization or plasma atomization. These processes involve:

Gas Atomization: Molten tantalum is atomized using high-pressure gas jets, which rapidly solidify the metal into small spherical particles as they cool.

Plasma Atomization: Tantalum feedstock is melted in a plasma arc and then atomized into fine droplets using high-speed gas jets, resulting in spherical powder particles.

These methods ensure uniform particle size and shape, essential for applications requiring high purity and precise material properties in industries like aerospace, electronics, and additive manufacturing (3D printing).

Tantalum (Ta), a refractory group metal. The main forms are metal powder, oxide and carbide. Tantalum powder is used primarily for manufacturing capacitors, semiconductor components, high-temperature alloys, and as a coating material for corrosion resistance and wear protection in industrial applications.

TANTALUM dust reacts rapidly with oxidizing agents (oxygen, fluorine, chlorine). Highly flammable in air, igniting spontaneously when dry.