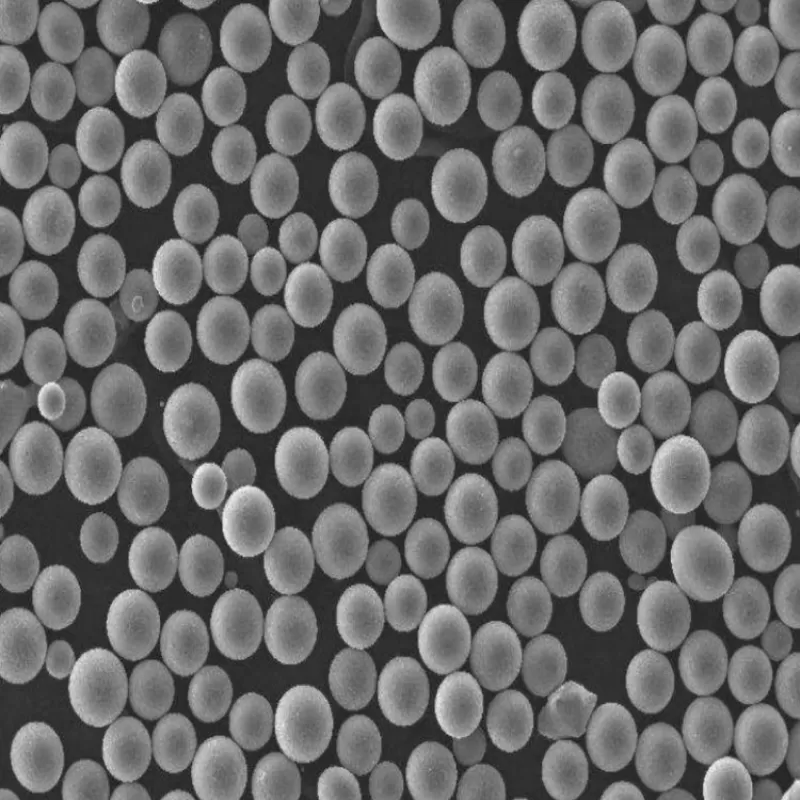

Spherical Aluminum(Al) Powder

Formula | Aluminium Al |

CAS Number | 7429-90-5 |

Purity | 99.7% min or Customize |

Synonyms | Aluminum particles, Aluminum sub-micron powder, Aluminum microparticles, Aluminum micropowder, Aluminum micro powder, Aluminum micron powder, Aluminum submicron powder |

Particle Sizes | 325 mesh or be customized |

Appearance | Black Color |

Melting Point | 660.37 °C |

Boiling Point: | 2467 °C |

Bulk Density | 1.24 g/cm3 |

Tap Density | 3.39 g/cm3 |

Related Products:

Spherical Tantalum powder (Ta Spherical powder)

Spherical Ti-6Al-4V (TC4) Titanium Based Metal Powder

Spherical Niobium Powder (Nb Spherical Powder)

Spherical Stainless Steel 316L Powder (SS316 Spherical Powder)

Spherical Stainless Steel 304L Powder (SS304L Spherical Powder)

Nickel Based Inconel 625 Spherical Powder

Nickel Based Inconel 718 Spherical Powder

Description of Spherical Aluminum Powder

Spherical aluminum powder is valued for its uniform spherical shape, which enhances flowability and packing density in manufacturing processes. Its high purity ensures minimal impurities, crucial for consistent performance in applications. Additionally, aluminum’s excellent thermal conductivity makes it ideal for efficient heat dissipation, while its lightweight nature and corrosion resistance contribute to its widespread use in aerospace, automotive, and marine industries.

Spherical Al powder includes various types: dark aluminum powder for pyrotechnics, grades available for sale, 3D printing-grade for lightweight components, fine aluminum metal powder for precision applications, and atomized aluminum powder known for its uniformity and enhanced flowability in manufacturing

Princeton Powder is a leading supplier of dark aluminum metal powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. With our expertise, we are confident in supporting your projects effectively and provide you with reliable solutions.

Spherical Aluminum Powder Applicable processes

Spherical aluminum powder is applicable to various manufacturing processes, including:

Additive Manufacturing (3D Printing): Used as a feedstock material to produce lightweight and high-strength components with intricate designs.

Powder Metallurgy: Blended with other powders to create alloys and components for automotive, aerospace, and industrial applications.

Coatings: Applied using thermal spray techniques to enhance surfaces with corrosion resistance and thermal insulation.

Pyrotechnics: Utilized in fireworks and explosives due to its fine particle size and rapid combustion properties.

Chemical Reactions: Used as a catalyst or reactant in chemical processes requiring high surface area and reactivity.

These applications leverage the spherical shape and properties of aluminum powder to achieve desired material characteristics and performance in diverse industries.

Spherical Aluminum Powder Chemical Composition

| Grade | Particle Size (um) | Activated Aluminium (≥%) | Impurity Content ≤% | ||||||

| Fe | Si | Cu | Mg | Zn | H2O | Total Impurities | |||

| 0# | ≥30 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| 1# | 26-29 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| 24-26 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 21-24 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 2# | 19-21 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| 17-19 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 15-17 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 3# | 13-15 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| 11-13 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 9-11 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 8-10 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 4# | 7-8 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| 6-7 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 5-6 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 4-5 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 5# | 3-4 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| 2-3 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 1-2 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

Benefits/Application of Spherical Aluminum Powder

Spherical aluminum metal powder is versatile, finding applications in additive manufacturing, powder metallurgy, coatings, pyrotechnics, and the chemical industry due to its uniform shape and beneficial properties like lightweight strength and corrosion resistance.

Spherical Aluminum Powder Reference

Preparation Method of Spherical and Monocrystalline Aluminum Powder

- This paper presents a new production method for a spherical and monocrystalline aluminum powder. Aluminum powder of irregular particle shapes was mixed with silica nanoparticles and heated to a temperature above the melting point of aluminum.

Several types of powders are used in 3D printing, depending on the specific printing technology and desired end-use applications.

- Metal Powders: Such as aluminum, titanium, stainless steel, and nickel alloys, used in powder bed fusion techniques like selective laser melting (SLM) and electron beam melting (EBM) to create metal parts.

- Polymer Powders: Including materials like nylon, polylactic acid (PLA), and polyamide (PA), used in selective laser sintering (SLS) and other polymer powder-based printing processes.

- Ceramic Powders: Such as alumina, zirconia, and silicon carbide, used in ceramic 3D printing methods for applications like dental restorations and aerospace components.

- Composite Powders: Mixtures of materials like metal and ceramic or polymer and metal, designed for specific performance characteristics in additive manufacturing.

Aluminum powder can be hazardous under certain conditions:

- Fire and Explosion Hazard: Fine aluminum powder is highly flammable and can ignite spontaneously in air. It poses a fire hazard if exposed to heat, sparks, or open flames. In confined spaces or when dispersed in the air as a dust cloud, it can explode if ignited.

- Health Risks: Inhalation of aluminum powder dust can cause respiratory irritation and may lead to lung damage over prolonged exposure. While not typically considered carcinogenic, chronic exposure to aluminum powder dust may contribute to respiratory issues.

- Handling Precautions: Proper handling procedures, including adequate ventilation, avoiding sources of ignition, and using appropriate personal protective equipment (PPE) such as dust masks and gloves, are essential to minimize risks when working with aluminum powder.

Aluminum powder is typically produced through a process called atomization, where molten aluminum is sprayed into a chamber and rapidly cooled by compressed air or inert gas. This forms fine particles of aluminum with a controlled size distribution, suitable for various industrial applications including additives, coatings, and 3D printing.