Spherical Niobium Powder (Nb Spherical Powder)

Formula | Niobium Nb |

CAS Number | 7440-03-1 |

Purity | 99.9% min |

Synonyms | Nb spherical particles, niobium Spherical particles, niobium spherical powders, niobium metal spherical powder |

Particle Sizes | 325 mesh or be customized |

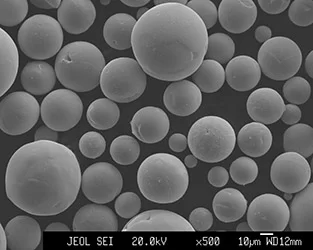

Appearance | Black grey powder |

Melting Point | 2468°C |

Boiling Point: | 4742°C |

Apparent Density | >4.5 |

Tap Density | >5.5 |

Description of Spherical Niobium Powder

Spherical niobium powder distinguishes itself from other forms of niobium due to its uniform spherical morphology, which not only enhances flowability and packing density in applications such as additive manufacturing and powder metallurgy but also provides a higher specific surface area advantageous for catalytic reactions, enables precise control over purity and particle size distribution critical for uniform alloying processes, improves handling by reducing powder clumping and ensuring consistency in automated manufacturing, and supports a wide range of advanced applications including aerospace, electronics, and energy sectors where its unique physical characteristics contribute to the development of high-performance materials and technologies.

Princeton Powder is a leading supplier of Spherical Nb powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. With our expertise, we are confident in supporting your projects effectively and provide you with reliable solutions.

Spherical Niobium Powder Chemical Composition

Chemical Composition by ICP-AES | Wt % |

Nb | ≥ 99.9 |

Ta | <0.05 |

Cu | <0.001 |

Al | <0.002 |

W | <0.005 |

Mn | <0.002 |

Mo | <0.003 |

Si | <0.002 |

Fe | <0.005 |

Cr | <0.002 |

Ni | <0.002 |

Ti | <0.002 |

Gas Impurities | |

O | ≤0.06 |

N | ≤0.003 |

C | ≤0.03 |

P | <0.002 |

Spherical Niobium Powder Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Benefits/Application of Spherical Niobium Powder

Spherical niobium powder finds application in various high-tech industries due to its unique properties.

- Additive Manufacturing: for 3D printing high-performance parts.

- Catalysis: as a catalyst or catalyst support.

- Advanced Ceramics: for sintering and composite materials.

- Alloys: to enhance properties like strength and corrosion resistance.

- Superconductors: in applications such as MRI machines and quantum computing.

- Battery Technology: for improved electrode performance.

Spherical Niobium Powder Reference

Development of niobium powder injection molding: Part I. Feedstock and injection molding

- This article details a systematical approach to develop feedstock for powder injection molding of niobium. It has been proven that powder injection molding is a viable forming technique for pure niobium.

High-quality spherical niobium powder is employed in thermal spray coatings, capacitors, superconductors, additive manufacturing, biomedical implants, and other cutting-edge applications.

Spherical powder is a type of gunpowder with small, round particles. It’s known for consistent metering, reliable burn rates, and efficient space utilization in cartridges.

Ball powder consists of small spherical granules, whereas flake powder is characterized by thin, flat, and often irregularly shaped flakes. The difference lies in their physical form, affecting how they meter, ignite, and burn in firearms.