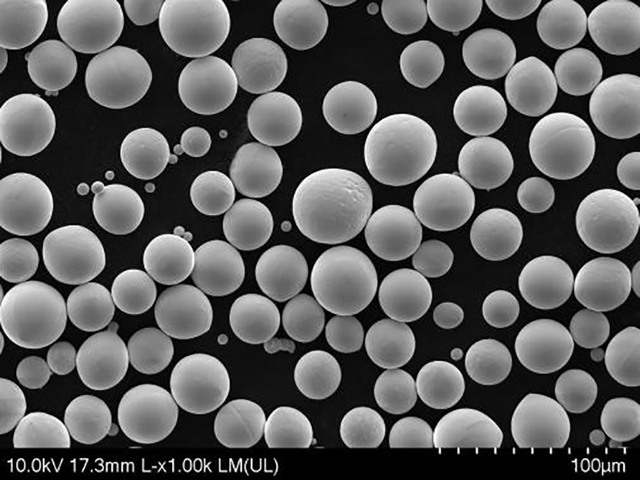

Nickel Based Inconel 625 Spherical Powder

Formula | Inconel 625 |

Synonyms | Inconel 625 spherical particles,IN625 spherical powders, Nickel Based Metal Powder, Inconel 625 thermal spray powder, Inconel 625 gas atomized powder |

Appearance | Black Powder |

Particle Size | 0-45 um, 45-105 um, can be customized upon request |

Melting Point | 1288–1349°C |

Density | 8.44 g/cm 3 |

Tap Density | >5.0 g/cm³ |

Apparent density | 4.32g/m3 |

Description of Inconel 625 Spherical Powder

Inconel 625 is a nickel-based superalloy known for its high strength, excellent corrosion resistance, and outstanding weldability. Typically consists of approximately 60% nickel, 20% chromium, 9% molybdenum, 5% niobium (columbium), and smaller amounts of iron, tungsten, and other elements.

Inconel 625 spherical powder is a specialized form of metal powder used primarily in additive manufacturing processes such as laser powder bed fusion (LPBF) or selective laser melting (SLM).

Princeton Powder is a leading supplier of IN625 metal powder. We specialize in a comprehensive range of spherical powder products and possess extensive expertise in additive manufacturing (3D printing) industry. With our expertise, we are confident in supporting your projects effectively and provide you with reliable solutions.

Chemical Composition

Chemical Composition:

Chemical Composition (wt%) of Inconel 625 | ||||||||||

Item | Fe | C | Mn | Si | Ni | Cr | Mo | V | W | Al |

In625 | ≤5.0 | ≤0.1 | ≤0.5 | ≤0.5 | Bal. | 20.0~23.0 | 8.0~10.0 | – | – | ≤0.4 |

Mg | Cu | Ti | Nb | Zr | P | S | Co |

|

| |

– | ≤0.07 | ≤0.4 | 3.15~4.15 | – | ≤0.015 | ≤0.015 | ≤1.0 |

|

| |

Oxygen≤400 ppm; Nitrogen≤300 ppm

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

Spherical Inconel 625 powder due to its exceptional properties, finds extensive application across various industries, primarily where high strength, excellent corrosion resistance, and heat resistance are crucial.

Aerospace Industry: Gas Turbine Components and Aircraft Exhaust Systems

Nuclear Reactor Components

Marine Industry: Offshore and Subsea Equipment

Additive Manufacturing

Spherical Inconel 625 Powder Reference

Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting

- Selective laser melting (SLM), an additive manufacturing process, is capable of manufacturing metallic parts with complex shapes directly from computer-aided design (CAD) models. SLM parts are created on a layer-by-layer manner, making it more flexible than traditional material processing techniques.

Titanium is a lightweight metal with an excellent strength-to-weight ratio. It also has good corrosion resistance when exposed to acidic environments. On the other hand, Inconel 625 is a nickel-based alloy that has higher strength and durability compared to titanium.

Inconel 625 powder is a finely ground form of the nickel-based superalloy Inconel 625. It’s used in additive manufacturing processes like laser powder bed fusion (LPBF) and selective laser melting (SLM). Known for its high strength, excellent corrosion resistance, and weldability, it’s ideal for aerospace, chemical processing, and marine applications where durability and performance under extreme conditions are crucial.

Inconel powder, like Inconel 625, is not flammable under normal conditions. It’s made of metals like nickel and chromium, which don’t burn easily. However, handling any fine metal powder requires safety precautions to avoid fire hazards from sparks or high temperatures.