Tungsten Rhenium Alloy Powder (W-25Re)

Formula | Tungsten Rhenium Alloy (W-25Re) |

Synonyms | spherical Tungsten Rhenium particles, spherical Tungsten Rhenium powders, W-25Re Powder |

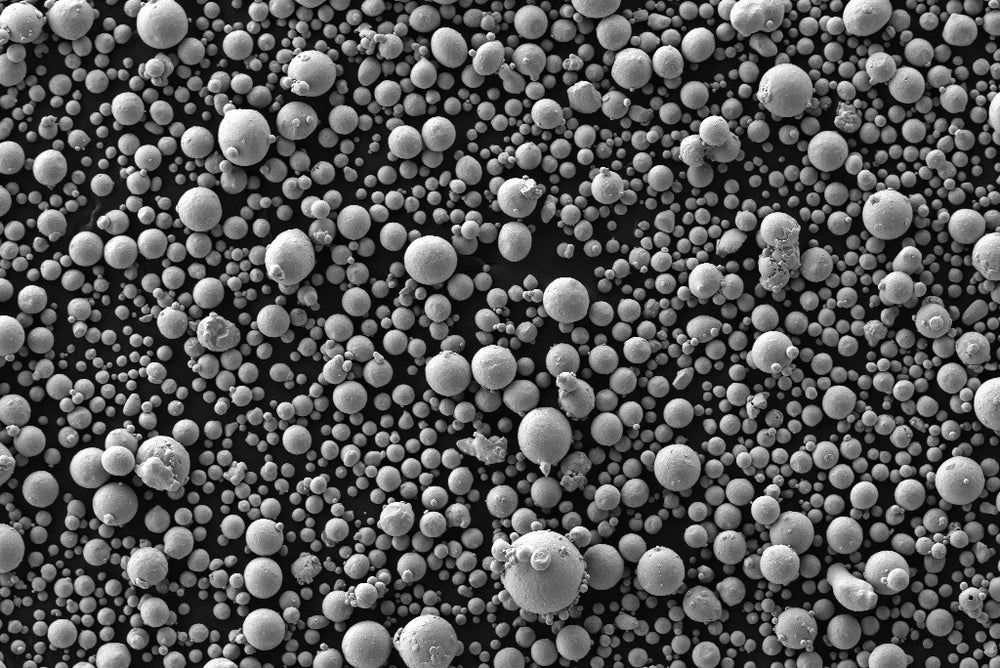

Appearance | Gray Powder, Spherical Morphology |

Particle Size | 15-53 um, 45-105 um, can be customized upon request |

Melting Point | 3100°C |

Density | 19.65 g/cm 3 |

Purity | 99.9% |

Tap Density | >11.5g/cm3 |

Related Products:

Spherical Stainless Steel 304L Powder (SS304l powder)

Spherical Titanium Ti-6Al-4V TC4 Powder

Spherical Nickel Based Inconel 625 Powder

Molybdenum Rhenium Alloy Mo-Re Spherical Powder

Spherical Tungsten Molybdenum Alloy W-Mo Powder

Spherical Tungsten Nickel Iron W-Ni-Fe Powder

Spherical Tungsten Nickel Copper W-6Ni-4Cu Powder

Description of Spherical Tungsten-Rhenium Alloy Powder

Spherical tungsten-rhenium alloy powder combines tungsten with a small percentage of rhenium, enhancing high-temperature performance and ductility. The powder is produced in a spherical shape through atomization, improving flowability and uniformity. It offers exceptional high-temperature strength, thermal stability, and hardness. This alloy is used in aerospace components, high-temperature electronics, and other advanced applications requiring extreme temperature resistance. The powder is manufactured by atomizing molten tungsten-rhenium or through powder metallurgy techniques.

Princeton Powder is a leading supplier of tungsten-rhenium alloy powder. We possess extensive expertise in additive manufacturing (3D printing) industry. Tungsten Rhenium Alloy W-25Re Powder is for sale at a competitive price.

Chemical Composition

Product | Particle Size(μm) | Chemical Composition(%) | ||||||||

W | O | Re | ||||||||

WRe3 | 2.0-4.0 | ≧96.9 | ≦0.12 | 3 | ||||||

WRe5 | 2.0-4.0 | ≧94.9 | ≦0.12 | 5 | ||||||

WRe15 | 2.0-4.0 | ≧84.9 | ≦0.12 | 15 | ||||||

WRe25 | 2.0-4.0 | ≧74.9 | ≦0.12 | 25 | ||||||

WRe26 | 2.0-4.0 | ≧73.9 | ≦0.12 | 26 | ||||||

Physical Properties | ||||||||||

Apparent Density (g/cm3) | Tap Density (g/cm3) | Hall Flow Rate (s/50g) | ||||||||

>10.0 | >11.5 | <10.0 | ||||||||

Particle Size distribution

0-15μm, 15-53μm, 45-105μm, 45-150μm. (Various particle sizes can be customized)

Applications

- Aerospace: Utilized in rocket nozzles and aerospace components for its high melting point and thermal stability.

- Electronics: Employed in the production of electrical contacts and filaments due to its high electrical conductivity and resistance to high temperatures.

- Medical Equipment: Used in radiation shielding and high-temperature environments where durability and stability are crucial.

Spherical WRe25 Powder Reference

Resolving the sintering conundrum of high-rhenium tungsten alloys

- Four compositions, W-1Re, W-5Re, W-10Re, and W-25Re, were studied. Before pressed into pellets, the synthesized W-Re nano powders were sieved by centrifuge to improve their sinterability (Morphology and phase purity of the nano powders are shown in Supplementary Figs. S1 and S2, respectively.) .